Flow meters are industrial tools used to measure important characteristics (volume, mass, and velocity) of fluid flows in various applications. Fluids measured include liquids, gas, and vapor. Most often, flow meters are used to measure the characteristics of volume, mass, and velocity. Such measurements can occur either via direct methods or indirect methods that infer characteristics from other parameters. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

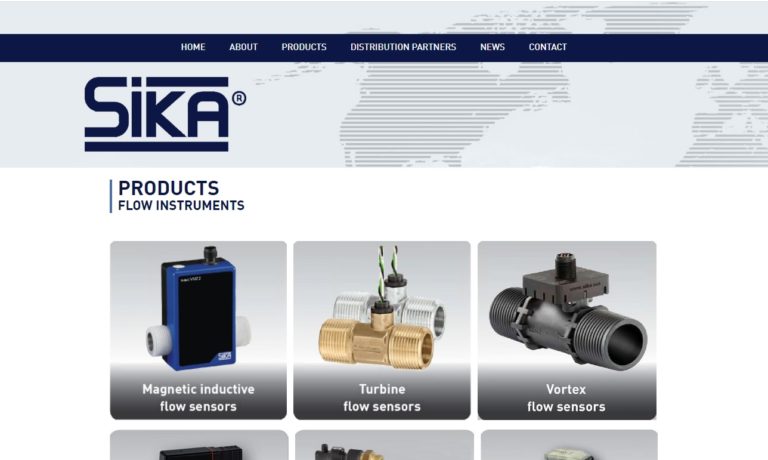

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

More Flow Meter Manufacturers

Flow meters can measure many other things as well, such as absolute pressure, differential pressure, viscosity, and temperature. While flow meters are often applied to fluid flows within enclosed systems (e.g. pipes), some of them are able to be applied to open channels. Depending on their specific application, these important devices may be known by alternate names such as flow gauges, flow indicators, or liquid meters.

History of Flow Meters

Measuring flow measurement has been an important aspect of commercial activity since the earliest times. Ancient Sumerian cities devised crude ways of flow measurement in order to fairly distribute water resources via aqueducts and other irrigation systems. In a similar fashion, ancient Egyptians devised weir rudiments (to assess the Nile and predict the imminent flood and harvest) while the ancient Chinese state of Qin utilized rudimentary flow measurement tools for their governmental irrigation system.

Modern forms of flowmeters can be traced back to 1738. In that year, Swiss Daniel was able to successfully judge characteristics of water flow by the use of differential pressure. In 1791, an Italian named Venturi devised the Venturi tube to measure liquid flow. Almost a century later, an American inventor named Hershel improved upon this device and enabled it to measure flows in open channels. Flow meters did not really develop, however, until a surge of industrial production and innovation following World War II. In the 1960s, flow meters were vastly improved by advancements in miniaturization and precision technology. Since an upward commercial surge in the 1990s, the use and spread of flowmeters has only continued to grow.

Flow Meter Parts and Configurations

Flow meters are made from a variety of materials, including plastic and industrial metals like bronze and iron (e.g. cast, ductile). Some flow meters are built with specially selected materials that will maximize results. Generally speaking, flowmeters possess three main elements known as the primary device, transducer, and transmitter (or pressure transmitter). The transducer and transmitter are heavily interdependent on each other since the transducer senses fluid flow through the primary device and the transmitter translates the information from the transducer into a signal that can be interpreted.

It should be noted that flowmeters can be installed and used in a variety of configurations. For example, flowmeters can have several devices attached to them, or they can be incorporated into a larger industrial system. Broadly speaking, flow meters are installed in one of three mounting styles: insertion, in-line, and non-invasive.

In-line flow meters integrate within a larger system. In contrast, insertion flow meters take measurements at a single location while non-invasive flow meters take measurements in some remote manner. An example of the former is a flowmeter inserted at a specific location on a pipe and used to infer fluid flow for the entire pipe. An example of the latter is an ultrasonic flow meter that reads shifts in frequency (or more specifically, the Doppler effect) caused by solid or gas suspensions in a fluid flow.

Types of Flow Meters

Like many industrial instruments, flow meters are marked by a broad range of diversity. Flow meters can be categorized in a number of different ways, including how they operate and what they specifically measure. Common types of flow meter types include water flow meters, flow switches, fuel flow meters, peak flow meters, air flow meters, and ultrasonic flow meters.

How They Operate

Positive displacement (PD) flow meters are also known as volumetric flow meters because of their ability to directly measure the volume of a fluid flow (in cubic inches or liters). They measure liquid flow by trapping it, rotating parts in it, and measuring the created flow between the meter body and the seals. The output of a PD meter is directly proportional to the volume of the fluid flow through the meter. Some sub-categories under PD or volumetric meters include bi-rotor flow meters (e.g. oval gear or helical gear flow meters), reciprocating piston flow meters, rotary/oscillating piston flow meters, etc.

Velocity flowmeters are also used to determine the volume of a fluid flow. As their name suggests, however, they accomplish this task indirectly by measuring the velocity of a fluid flow first. The sub-categories underneath velocity flowmeters are many and include ultrasonic flow meters, time-of-flight meters (which measure flow rate through the use of sound) and turbine flow meters (which have rotors that measure fluid based on the speed of the blades that the fluid passes through.) The vortex flow meter (or vortex shedding flowmeter) is a particularly unique sub-category that measures flow rate by blocking the flow path with an obstruction (or bluff body) and forcing liquids or gases to move around it. When this occurs, two symmetrical vortices form on the opposite side, changing flow pressure. This pressure change is measured by a sensor placed in between the vortices, which then transmits its data to an electronic signal conditioner separate from the meter.

In contrast to volumetric flowmeters, mass flowmeters utilize mass flow measurement (measured in kilograms or pounds). On the other hand, mass flowmeters resemble volumetric flowmeters by producing an output signal that directly correlates to the mass of the liquid flowing through the meter. Coriolis mass and thermal flowmeters are some of the best-known flow meters that measure mass.

Inferential flowmeters interpret the aforementioned conditions (volume, velocity, and mass) based on their reading of other factors. Some good representatives of this category are differential pressure flowmeters and variable area flowmeters.

Magnetic Flow Meters and the Pharmaceutical Industry

With the importance of efficient and maintained pipeline networks, the demand for devices that automatically monitor pipe flow has only increased. One such device is the flow meter, which measures the volumetric flow of liquids, from which it can calculate the absolute and differential pressure in the liquid. In 2021, the flow meter market was estimated to be around USD 7.7 billion, with a projected change to USD 10.3 billion in 2026. The primary industries that use flow meters were found to be the water and wastewater industries, as they could be used in numerous parts of water and wastewater treatment, with the requirement of clean discharge of effluents.

From market research in 2020, it was found that magnetic flow meters, or magmeters, were the most widely used type of flow meter. Using electromagnetic induction, magmeters were shown to be used in food and beverage industries for their ability to be unaffected by changes in water characteristics such as concentration, density, temperature, viscosity, and electrical conductivity.

While other industries have embraced the use of magnetic flow meters, the pharmaceutical industry has been having problems with the usual types of flow meters. Due to their use of ultrapure water, magnetic flow meters were not an option for precise measurement due to the very low conductivity of the liquid. To solve this problem, Bürkert developed a flow meter called FLOWave that uses surface acoustic waves technology. This device has no direct contact with the liquid it is measuring and solves other issues that flow meters encounter, such as system vibrations and conductivity of the liquid, to name a few.

Proper knowledge and maintenance of your pipe networks are essential for an efficient workflow. In addition, new advancements in the industrial sector make it best to keep updated on the latest news and technologies.

What They Measure

Many flowmeters are simply identified by the phenomenon or substance they measure. Water flow meters are made to measure flow rates of water in various bodies, such as tubes, rivers, streams, channels, and partially filled pipes. Air flow meters simply measure the flow of air. Peak flow meters are made especially for use by asthma patients or others with breathing problems, so that doctors can measure their oxygen intake. Fuel flow meters (which may be positive displacement, ultrasonic, or turbine flow meters) take measurements of fuel usage rates from stationary pumps and transportation devices.

It is not uncommon for flowmeters to operate in conjunction with useful accessories. Flow switches differ from other meters in that they have a fourth component that controls flow as a switching unit, and they may set off an audible or visual alarm if the flow is too low or too high. Another example of a flow meter accessory is an observation window (sometimes known as a flow indicators) that helps to measure flow by providing a method of visual assessment.

Additional Information on Coriolis Flow Meters

THE CORIOLIS PRINCIPLE

The French mathematician Gustav Coriolis developed the Coriolis Principle in 1835. This principle says an inertial force needs to be taken into account when describing the motion of bodies in a rotating frame. For example, a hypothetical object thrown from the North Pole to the Equator appears to move from its intended path due to Earth’s rotation, and this illustrates the Coriolis Effect.

APPLICATIONS OF THE CORIOLIS EFFECT

The Coriolis Principle has some interesting natural and industrial applications:

METEOROLOGY: The Coriolis Principle is all around us in the world, such as in the rotation of the Earth and its impact on the weather. The Coriolis Effect has a big impact on the large scale dynamics of the oceans and the atmosphere. In oceans, the Coriolis Effect leads to the formation of features like jet streams and western boundary currents. During the formation of hurricanes, if the force from the Coriolis Effect is strong, the wind spins faster, making hurricanes stronger.

BALLISTIC TRAJECTORIES: In Ballistics, the Coriolis Force is used for calculating the trajectories of very long range artillery shells. The Coriolis Force minutely changes the trajectory of a bullet, affecting accuracy at extremely long distances. It is adjusted for by long distance shooters, such as snipers.

CORIOLIS FLOW METERS: These flow meters use the Coriolis Effect to quantify the amount of fluid passing through tubes or pipes. Coriolis flow measurement is the simultaneous measurement of mass flow, density, temperature, and viscosity. The Coriolis measuring principle is used in different branches of industry, such as the life sciences, chemicals, petrochemicals, oil and gas, food, and in custody transfer applications.

CORIOLIS FLOW METERS

Most commercially used fluids such as water, oil, gas, fruit juices, and chemicals are transferred using pipelines. Fluids, while inside pipelines, show very different properties. Structural characteristics of the pipeline and atmospheric conditions such as temperature and pressure will influence the fluid properties. Thus, measuring volume might provide inaccurate information. Coriolis flow meters allow the flow of mass to be directly measured rather than the volume.

MEASUREMENT OF MASS FLOW RATE

Coriolis flow meters can be considered true mass meters since they measure mass and not volume. Since mass does not vary, there is no need to adjust the flow meter for the characteristics of different materials.

The U shaped tube on a Coriolis flow meter is the most important part since its movements produce the meter’s readings. When a material enters the tube, it oscillates in an angular harmonic motion; this deforms the tube.

The excitor ensures the oscillation and the movement of the tube continue constantly. When there is no flow, the oscillation is uniform.

Sensors are located at the inlet and outlet to record the oscillation. Though the oscillation is uniform when there is no flow, it changes with the introduction of a fluid or gas. The liquid’s inertia forces the oscillation of the inlet and outlet sections of the tube to move in different directions. The sensors pick up the change in oscillation in terms of time and space; this change is known as phase shift.

The data acquired from the tube fluctuations and phase shift is fed into a flow meter that provides information on the mass, volume, and density of the fluid or gas.

Flow Meter Advantages

Flow meters form a very important part of the industrial world. On average, they are superior to point sensors, since they are able to gauge characteristics of an entire fluid flow within a system. Since flow meter techniques and designs are so varied, they are used by many different industries, such HVAC, construction, chemical and raw materials, paper/pulp, metallurgy, automotive, gas/petroleum, utility services, medical treatment, pharmaceuticals, and brewing.

Specific types of flow meters are often chosen to withstand certain environmental conditions in specific applications. For example, streamlined “gear meters” are ideal for laboratory testing that may involve hazardous conditions; ultrasonic flowmeters are well suited for unhygienic scenarios that typically damage conventional flowmeters; and vortex meters prove particularly useful in high temperature applications or applications that may involve rapid environmental changes.

Considerations When Selecting Flow Meters

When selecting a flow meter, there are many important factors that should be taken into consideration. However, the single most important factor to remember is that the intended application of a flow meter should outweigh any other considerations. Unfortunately, it is a common industrial practice to apply application-specific flow meters to scenarios for which they were never intended in order to save on initial investment or purchase costs. More often than not, this strategy fails over the long run and ends up costing a flow meter user far more than they would have spent otherwise. To give a single example, “two phase” fluid flows (e.g. a combined liquid/gas flow or liquid/solid flow) are notorious for plugging and disrupting the accuracy of many types of flowmeters. If a (relatively) cheap flowmeter is chosen for this type of application in order to cut upfront costs, it is almost certain that such an investment will backfire.

Generally speaking, the following factors should be assessed in the following order:

• How information from the flow meter will be obtained and read (e.g. does information need to be continuous or totalized, does it need to be shared remotely, how will it be shared remotely, etc.)

• The physical nature/characteristics of the actual fluid being sampled (e.g. viscosity, chemical composition)

• The nature of the piping or other infrastructure that will accommodate the fluid flow (e.g. diameter)

Some other factors to consider when choosing a flow meter are: maximum and minimum flow ranges (in terms of volume and mass), maximum and minimum operating temperatures and pressures, allowable pressure drops/differentials, and potential hazards in the surrounding environment (e.g. explosive gases).

By systematically working through these factors, you can usually arrive at the best flow meter for your application by process of elimination. For example, if the fluid you are sampling has a high level of viscosity, you can automatically eliminate turbine flow meters from your selection list.

The in-depth nature of flow meter selection illustrates the worth of a quality flow meter supplier. Finding the right supplier or manufacturer can dramatically expedite and streamline the entire flow meter selection process. Some suppliers provide customized tools (e.g. flow meter evaluation forms) along with professional advice in order to help you make the best possible choice for your application. Suppliers can also significantly help during the installation process (e.g. properly using a wiring diagram).

To function properly and give you the most accurate reading, flow meters must be handled using specific guidelines. For example, gas flow, air flow, and liquid flow meters alike, must remain full of their respective element in order to stay accurate. In addition, meter operators must watch for and remove any foreign contaminants from fluid, like gas in liquid flow meters, and must maintain or take into account air, fluid, or gas quality, as well as viscosity. To get the most out of your flow meter, certain practices should be avoided, including downward liquid flow applications or locating flow meters downstream from flow disturbances. (Both scenarios significantly affect flow meter precision and accuracy.) Like most industrial devices, flow meters should be regularly maintained to extend their commercial life. Consider investing in meters without moving parts, since they reduce the need for standard maintenance practices (e.g. lubrication) and eliminate the need for “clearance spaces” that can also affect meter accuracy. A well maintained and carefully monitored flow meter will provide essential information and thereby improve efficiency of operations, application safety, and application accuracy.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services