A flow gauge is a device used to measure the mass of a liquid or gas. The terminology used to refer to them depends on the industry, with names such as flow meters, flow rate sensors, liquid meters, and indicators. Flow gauges can measure the flow in a pipe or open channel and offer accurate flow and volumetric measurements. As a gas or liquid flows through a flow gauge, the media’s flow, volume, speed, and mass are measured. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

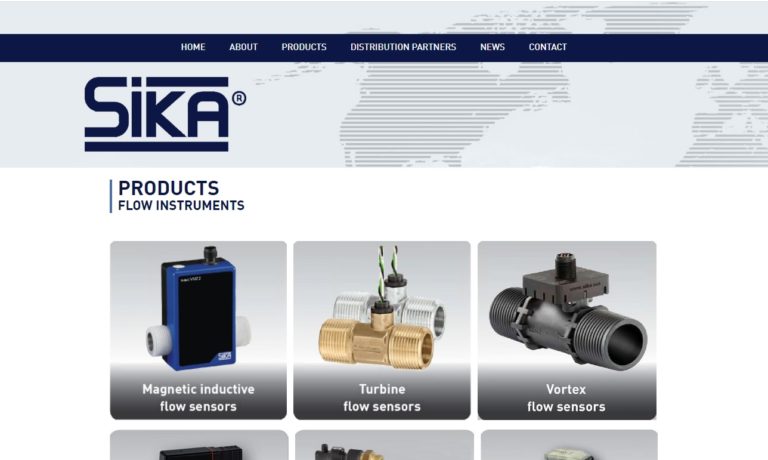

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Flow Gauge Manufacturers

Flow Gauge Classification

Flow gauges are designed to measure the flow of various liquids and gasses. The three groups of flow gauges are optical, mechanical, and open channel. Mechanical flow gauges are contact flow gauges that have a mechanical element in contact with the gas or liquid, while optical flow gauges are non-contact flow gauges and use light to measure flow velocity.

Mechanical Flow Gauge

A mechanical flow gauge has a moving part placed in the flow. There are four basic mechanical flow gauges: positive displacement, mass, differential pressure, and velocity. They are divided by their method to measure the flow rate and accuracy.

Positive Displacement Flow Gauges

Positive displacement flow gauges have chambers through which a fluid flows. Inside the chambers are components that separate the media into metered volumes. The liquid flow rotates, shifts, or displaces all the components. Positive displacement flow gauges provide highly accurate flow readings without needing a power supply.

Mass Flow Gauges

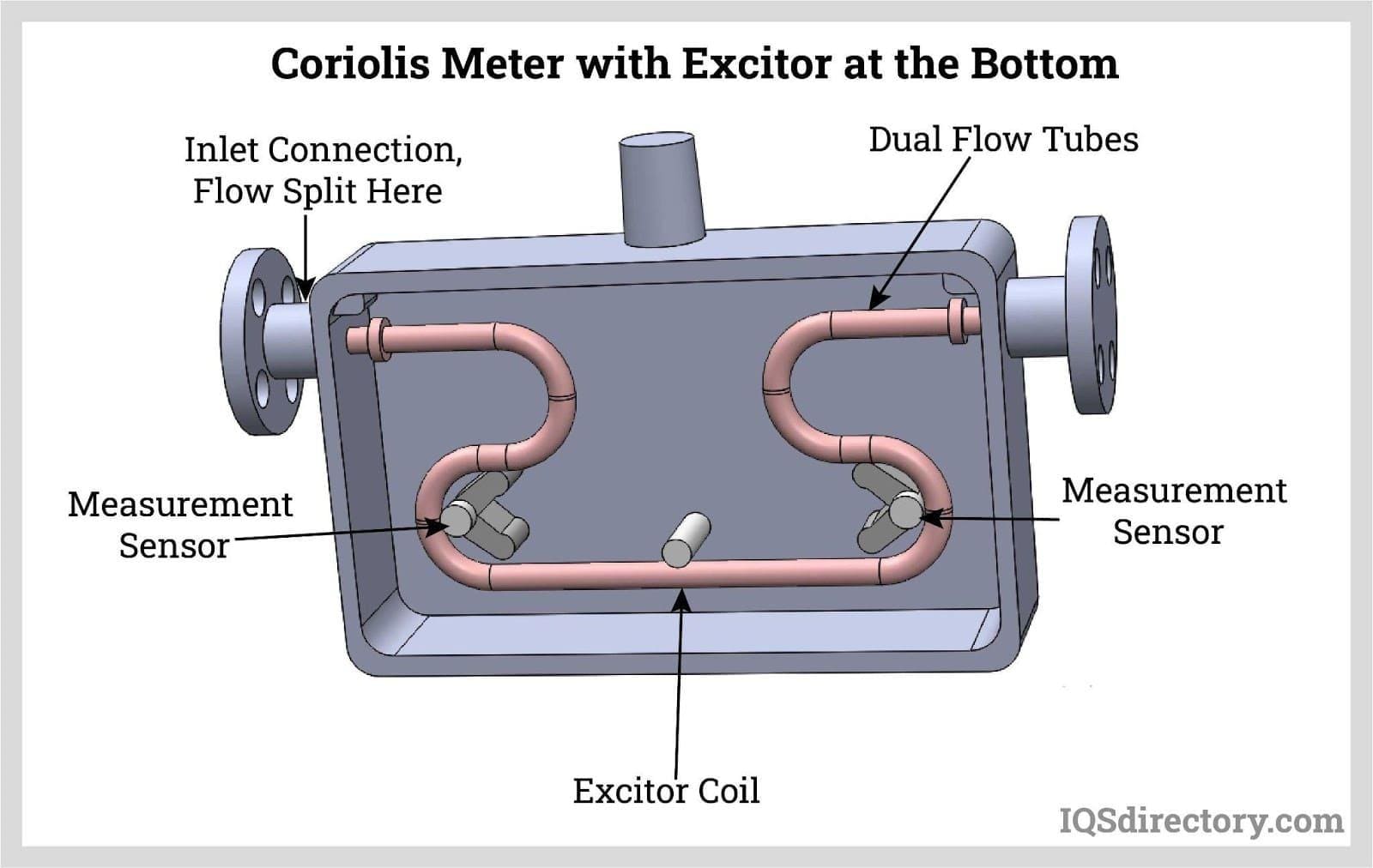

Mass flow gauges measure the volume of a media as it passes through them. They measure the mass of a media in mass per unit of time. The two types of mass flow gauges are Coriolis and thermal.

Coriolis Flow Gauges

Coriolis flow gauges are inertial flow gauges. As the media passes through a set of tubes, the tubes experience vibratory force, which causes oscillations in parts of the tube. The oscillations' amplitude, frequency, and phase shift are used to calculate mass flow.

Thermal Mass Flow Gauges

A thermal mass flow gauge uses heat transfer to measure mass flow rates. They have a heating element and temperature sensors. As the media passes by the heating element, it gains thermal energy, increasing the fluid's temperature. The sensors measure the amount of heat dissipation to calculate the flow rate.

Differential Pressure Flow Gauges

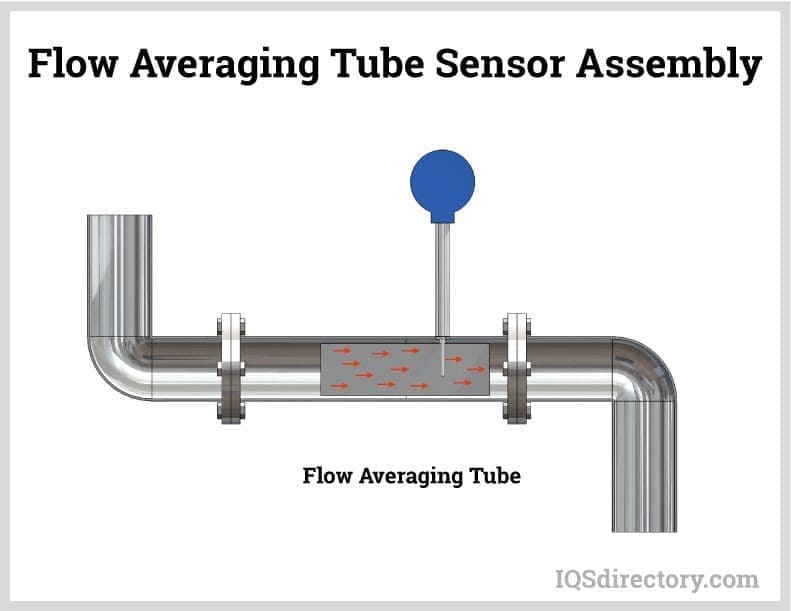

Differential pressure flow gauges block the flow of the media to create a disparity in the pressure between the up and downstream flow. The difference in the pressures is used to measure the flow rate. They are a very popular type of flow gauge due to their low price and simple design.

Velocity Flow Gauges

Velocity flow gauges measure flow speed using various mechanical methods such as turbines, paddlewheels, electromagnetics, vortex shedding, and ultrasound. The principle of a velocity flow gauge is based on the concept that fluid velocity is directly proportional to the volumetric flow rate given the constant density of the fluid flow stream.

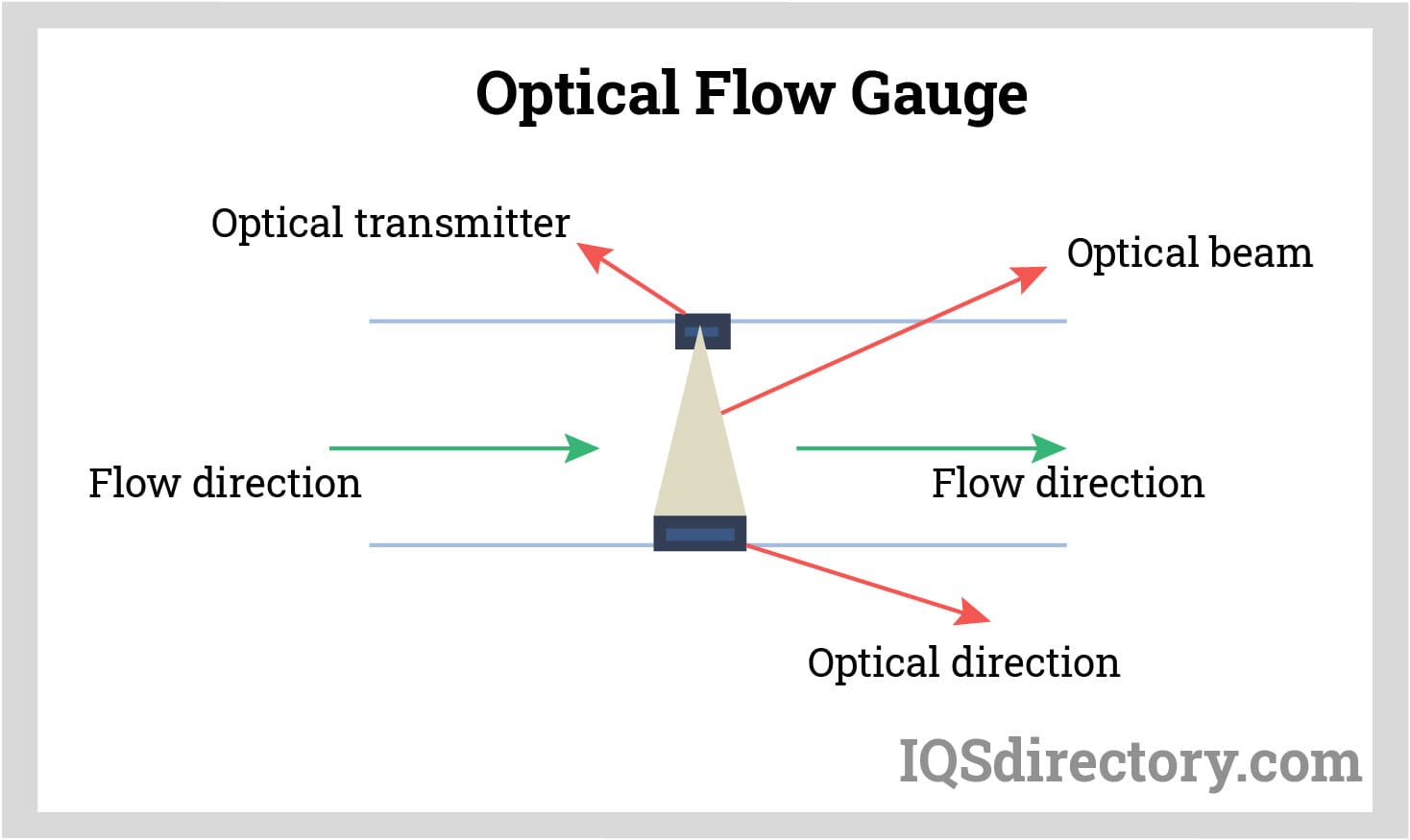

Optical Flow Gauges

Optical flow meters measure the flow rate using a laser beam and photodetectors. As the media passes through a pipe, it scatters the laser beams and produces pulses detected by a receiver. The time between the signals is determined by the distance between the photodetectors, which measures the speed of the media. Optical flow gauges are unaffected by thermal conditions or variations in flow, making them effective in hostile environments.

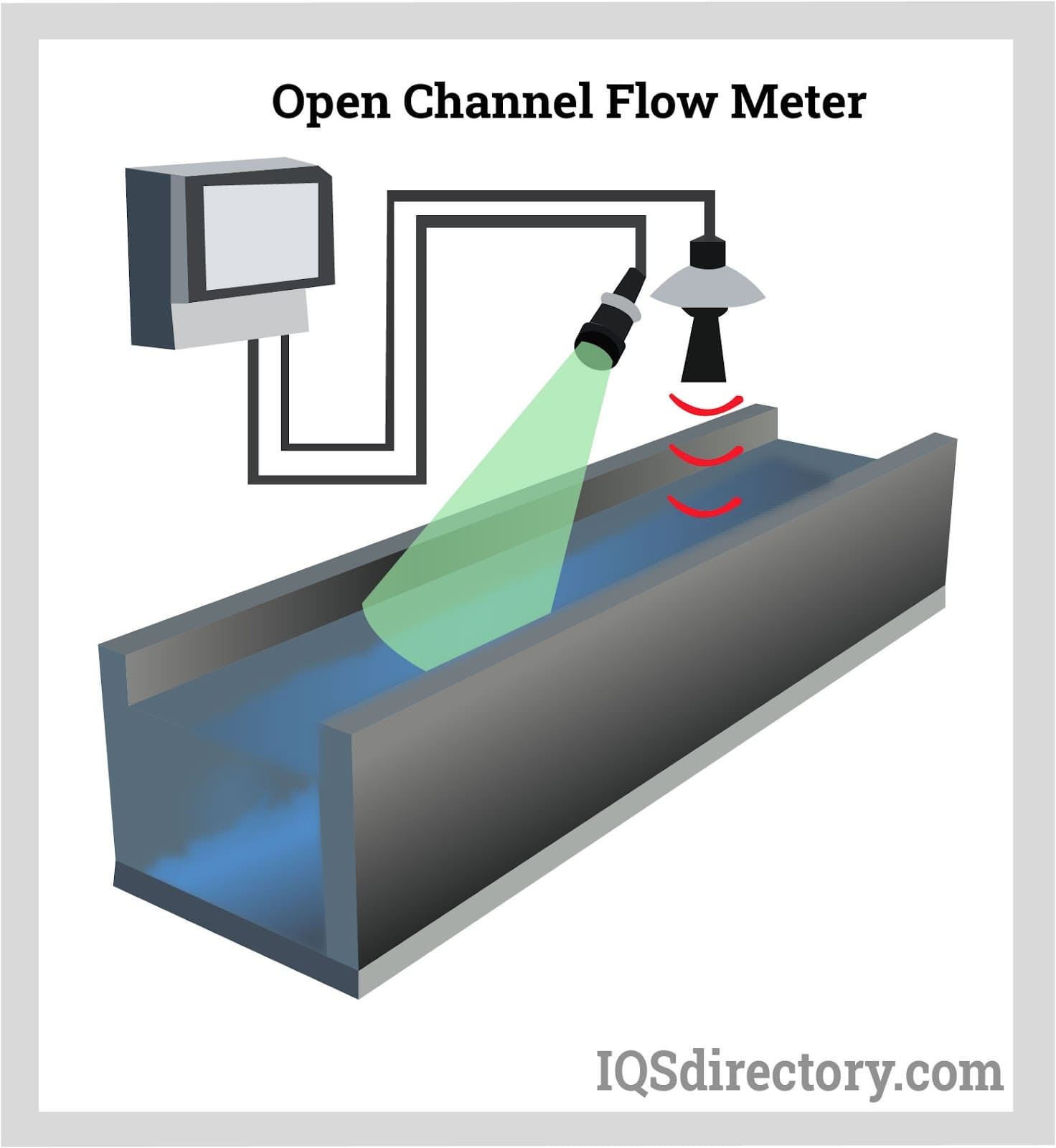

Open Channel Flow Gauges

The measure of open channel flow is challenging since there is a single surface upon which the flow occurs. Unlike a pipe, where the walls restrict the flow, open channel flow is free-flowing, constrained only by gravity. The shape of the flow is determined by the shape and configuration of the channel.

Open channel flow gauges measure the relationship between the depth of the fluid and the flow rate. They use ultrasonic transducers, pressure sensors, shaft encoders, radar, and other methods to measure flow rate. Open channel flow gauges are used to measure flow through weirs, flumes, and channels and are non-contact flow gauges that measure the flow level to calculate the flow rate and volume.

Uses for Flow Gauges

Flow gauges are important tools that accurately measure fluid and gas flow to ensure the efficient performance of an application. The data they provide helps monitor a system and prevent problem areas from becoming uncontrollable. As a result, they have an endless number of industrial uses.

Petroleum Production

The petroleum industry makes the greatest use of flow gauges since it is based on the efficient use of liquids and gasses. Flow gauges are used at every stage of the production process to record fluid flow and quantities.

Chemical Industry

In the chemical industry, flow gauges have the multiple tasks of conducting accurate flow measurements and controlling production to prevent catastrophic conditions. The accuracy of flow meters ensures proper measurements of chemicals for a mixture to guarantee quality.

Gas Stations

Flow gauges measure the gas received by the station and the gas provided to customers. They must be accurate due to the cost involved with gas sales and distribution. These three industries are a small sampling of the many industries that depend on the reliability and accuracy of flow gauges.

Choosing the Right Flow Gauge Supplier

To ensure the most productive outcome when purchasing flow gauges from a flow gauge supplier, it is important to compare several companies using our directory of flow gauge suppliers, Each flow gauge supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each flow gauge business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple flow gauge companies with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services