The mass flow rate of a liquid or gas traveling through a pipe is precisely measured by a mass flow meter, a kind of flow meter. Volumetric flow rate, which calculates the volume per unit of time,differs from mass flow rate. Mass flow rate is measured in mass per unit of time. Most formula formulations, material balance calculations, invoicing calculations, and custody transfer processes are based on mass flow measurement. The accuracy and dependability of mass flow sensing are crucial since these are the most crucial flow metrics in a processing facility. The majority of formula formulations, material balance calculations, invoicing calculations, and custody transfer processes are all based on mass flow measurement. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

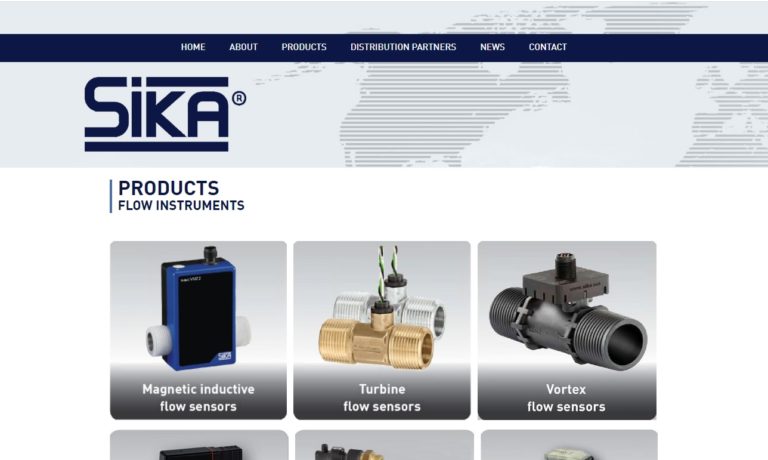

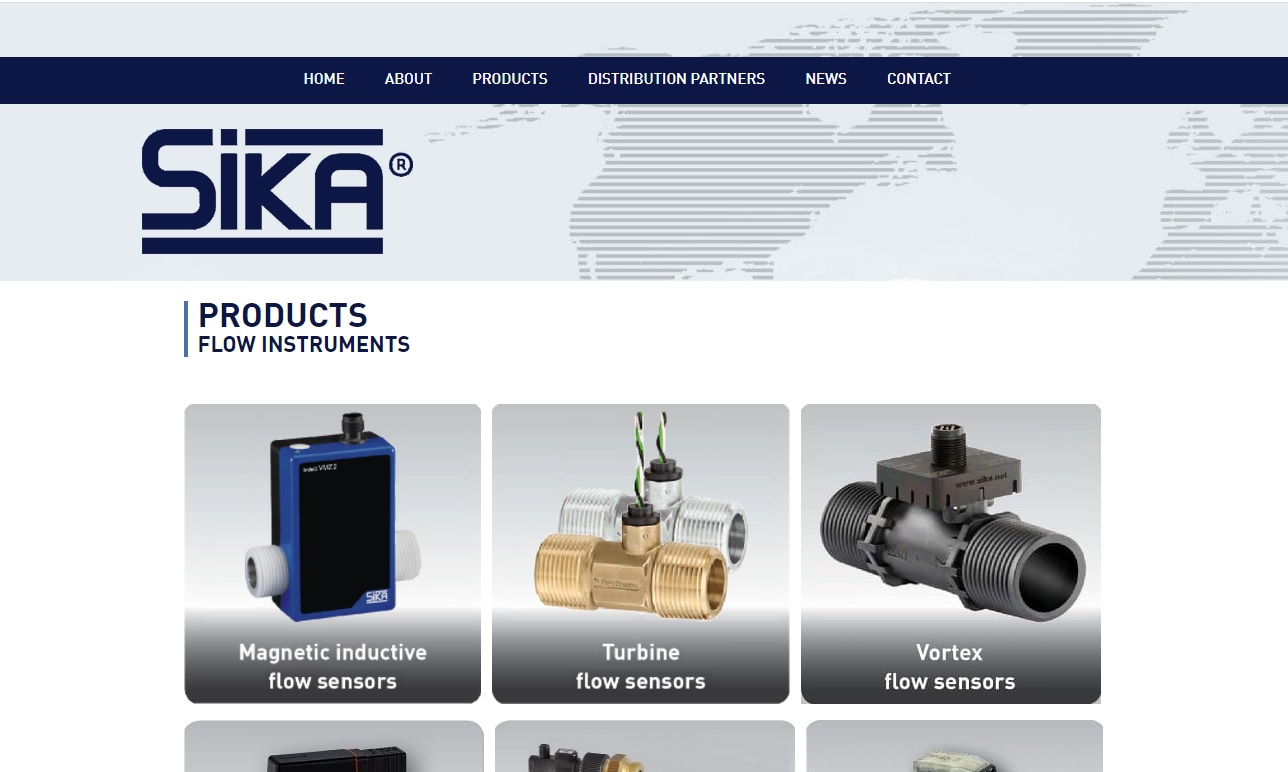

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Mass Flow Meter Manufacturers

Flow meters are instruments that gauge how quickly a fluid is moving through a system. Mass flow meters and volumetric flow meters are the two primary divisions of flow meters in general.

Principle of Operation

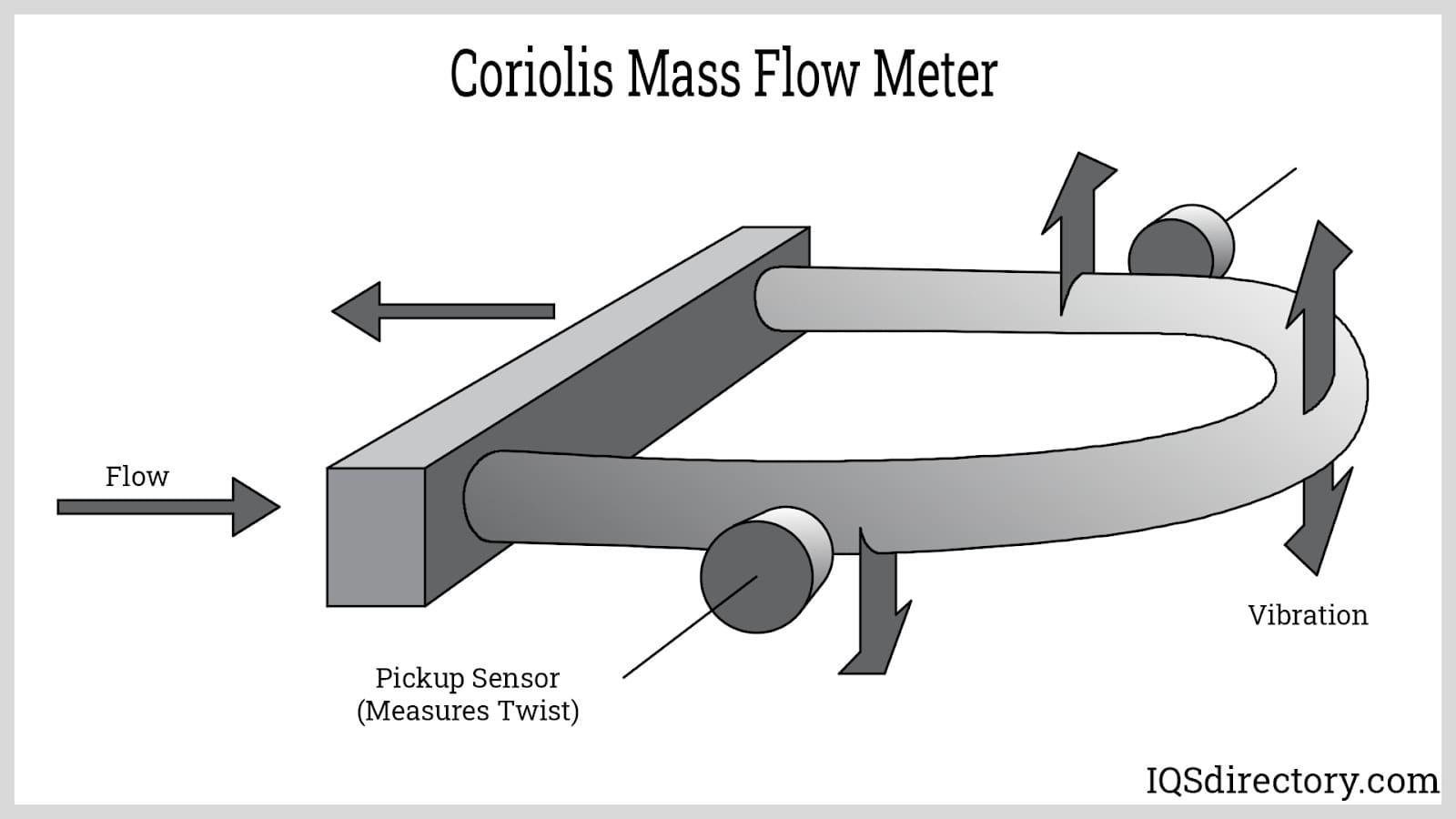

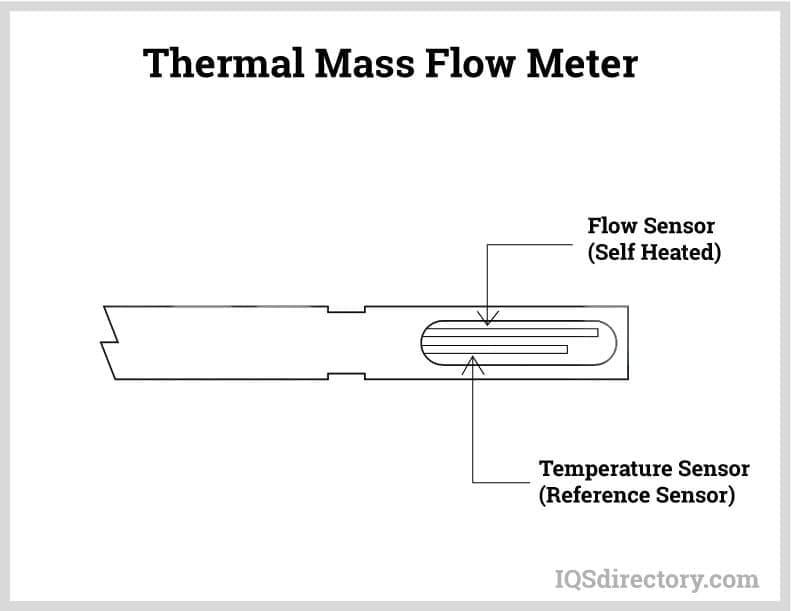

Thermal and inertial flow technologies are employed to measure mass flow. The Coriolis effect is used by inertia meters, also called Coriolis mass flow meters, to calculate mass flow rate. The amount of deflecting force produced by the Coriolis inertial effect depends on the mass rate at which the fluid flows when it flows in a pipe and is exposed to Coriolis acceleration via the mechanical introduction of visible rotation into the pipe. Heat mass flow meters use a heat source and temperature sensors to operate using the heat transfer principle to directly quantify gasses and liquids’ mass flow rate.

Direct Measurement of Mass Flow

This mass flow measurement minimizes errors brought on by the differences between volumetric flow and mass, among other fluid-related physical characteristics. A major justification for the employment of mass flow meters is that this type of mass flow measurement is an absolute indicator that is taken straight from the stream of the medium and is not impacted by temperature, pressure, viscosity, or density fluctuations. Volumetric measuring equipment remains accurate as long as the circumstances and benchmark calibrations are carefully followed. Unfortunately, temperature or pressure variations that alter flow rate cannot be detected by volumetric devices like turbine flow or variable area meters.

Coriolis Theory

The Coriolis principle describes how a rotating mass affects a body in motion. The Coriolis force, which is applied to the body by the moving mass, causes deformation and appears to cause the body to veer off course. The Coriolis flow meters operates on the tenet that the force, rather than acting directly on the body, acts on the motion of the body. The Coriolis idea is extremely simple but very powerful. It makes use of a pipe that is powered by constant vibration. The tube’s resonance is altered by the flow rate momentum when a fluid flows through it, causing a phase shift. An output that is linear and equal to the flow is produced from the phase shift. Any gas or liquid can be measured for mass flow using the Coriolis method because it is not dependent on the substance in the tube. The natural frequency, which varies in proportion to the density of the fluid, can also be measured in addition to the phase shift frequency. It is possible to determine the flow rate of the volume using the density and the mass flow from the phase shift. Direct flow meters that use the Coriolis effect are called Coriolis meters. Greater flow rates and reduced pressure loss are possible due to the straight-through flow path through the meter.

Thermal Mass Flow Meters

These types of mass flow meters are precise instruments used to measure the mass flow of various gasses directly. They place a sensor into a gas stream of a duct to monitor the gas flow utilizing convective heat transfer. A heat mass flow meter's tip is equipped with two resistance temperature detector (RTD) sensors that measure thermal performance as fluid flows over a heated surface. An integrated circuit heats one of the RTDs while the reference RTD gauges the gas's temperature.

Turbine Flow Meters

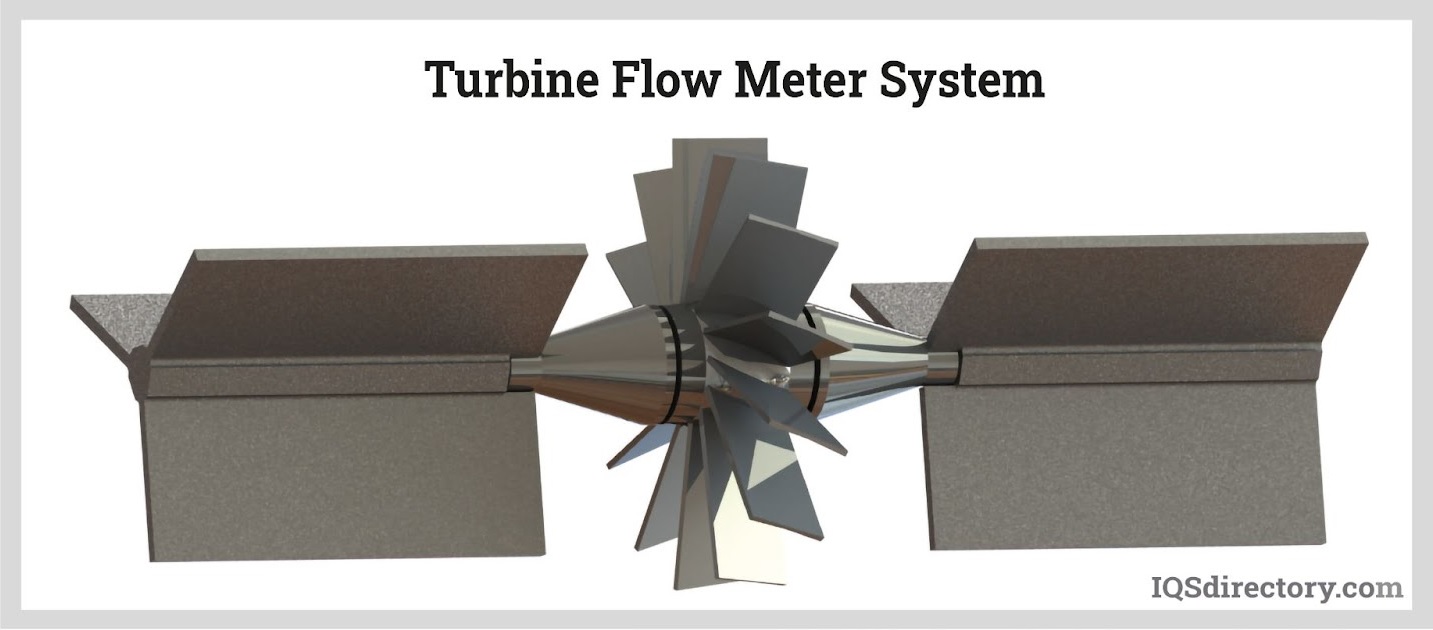

This type of flow meter uses a rotor with slanted blades that quickly revolve in a counterclockwise or clockwise direction to measure the energy generated by the flow. The rod to which the blades are fastened rotates smoothly because of the bearings in the rod. The flow's quick motion quickens the blades' rotation rate, which spins the rod. Magnets, temperature sensors, and pressure sensors are fastened to the blades to measure the flow rate.

As they rotate, the blades pass a small metal object adjacent to the meter. The time taken for the rotors to pass the given object gives a precise reading of the flow rate.

Choosing the Right Mass Flow Meter Supplier

To ensure the most beneficial outcome when purchasing mass flow meters from a mass flow meter supplier, it is important to compare several companies using our directory of mass flow meter suppliers. Each mass flow meter supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each mass flow meter business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple mass flow meter companies with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services