Ultrasonic flow meters are available in both single and dual-sensor versions though models using two sensors are more common and may be more accurate. Ultrasonic flow meters are ideal for wastewater applications or any dirty liquids that are conductive or water-based. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

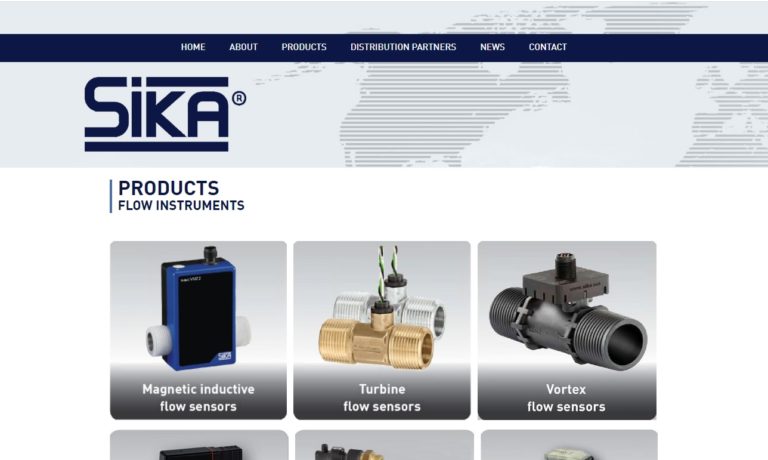

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Ultrasonic Flow Meter Manufacturers

Ultrasonic flow meters are ideal in situations where low-pressure drop, chemical compatibility, and low maintenance are required. However, ultrasonic flow meters will generally not work with distilled water or drinking water because they are too clean and pure in which case water flow meters are the best option. These flow meters are made out of metal such as steel when used inline.

Important considerations to keep in mind while choosing an ultrasonic flow meter include the size of the pipe, the minimum/maximum flow rate required, and the minimum/maximum process temperature and pressure needed. Also, determining whether a handheld or continuous process monitor is necessary is also important. Many meters of this kind do not need to be part of the pipe system but can be installed outside of the piping. Ultrasonic flow meters are widely used by many industries that work with free flowing liquids.

The basic principle of operation employs the Doppler Effect which is the term used to refer to a shift in frequencies when an ultrasonic signal is reflected by discontinuities in the form of suspended particles or bubbles in motion. Ultrasonic sound is transmitted through a transducer into a pipe with flowing liquids. The solid particles or air bubbles reflect the ultrasonic wave with a slightly different frequency that is directly proportional to the rate of flow of the liquid. A second transducer picks up the reflecting waves and reports the difference. This process allows the meter to get an accurate measure of the liquid's flow rate.

Clamp-on type flow meters are another option. They measure the flow through the pipe without requiring any parts to be exposed to the stream, ensuring that corrosion and other effects from the fluid will not damage the sensors. Plastic or metal-housed transducers are placed on opposite sides of a pipe and are connected to a handheld electronic device that can provide a reading as well as trend patterns and other details.

Many designs besides clamp-on types are portable, a feature particularly useful for acting as a backup for a preexisting flow meter or for double-checking existing meters in a number of locations.

Ultrasonic flow meters may be specially adapted to measure the flow rate of gasses while others are meant for use in open channels. Flow switches may be added if a report or alarm is desired.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services