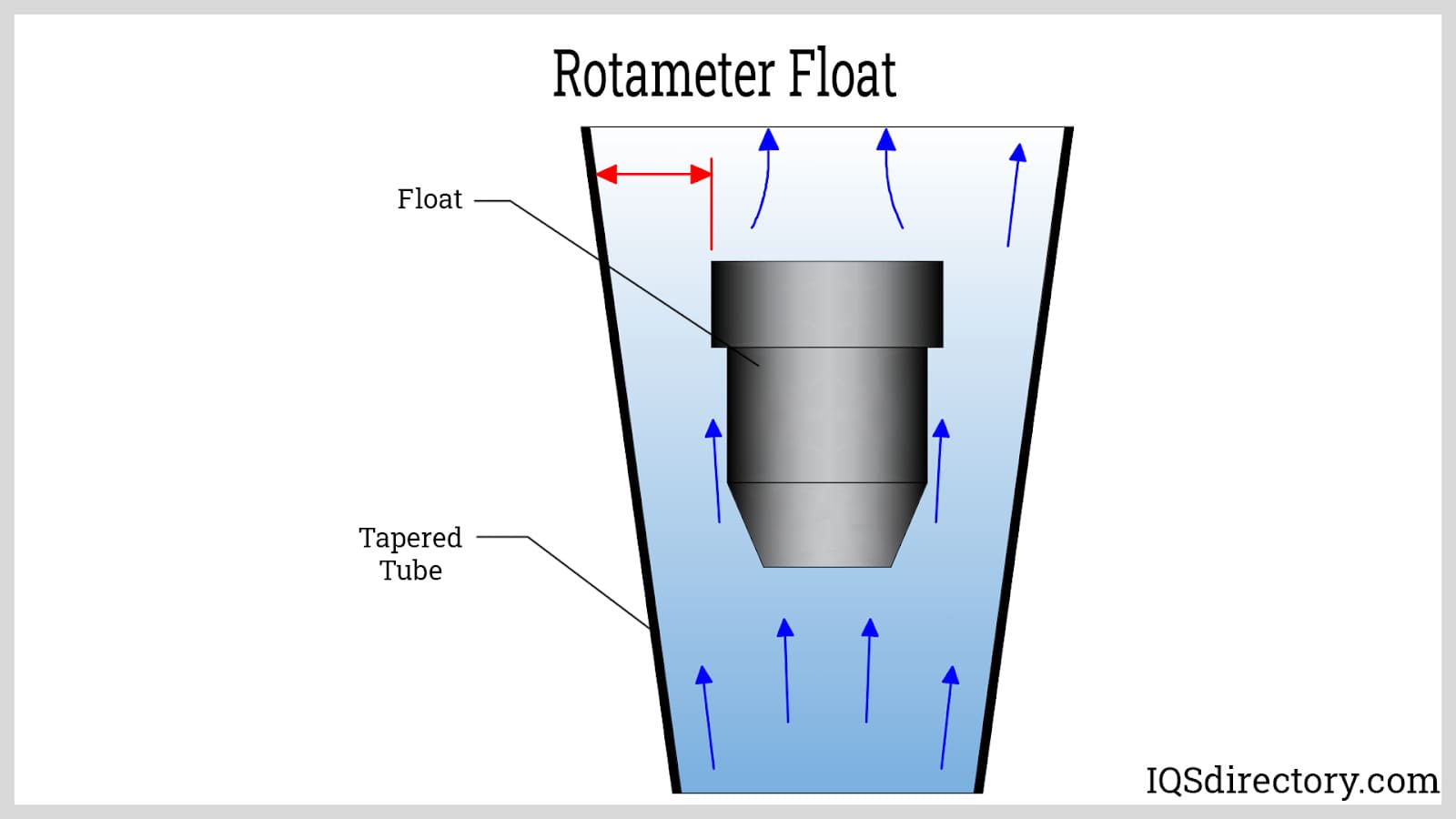

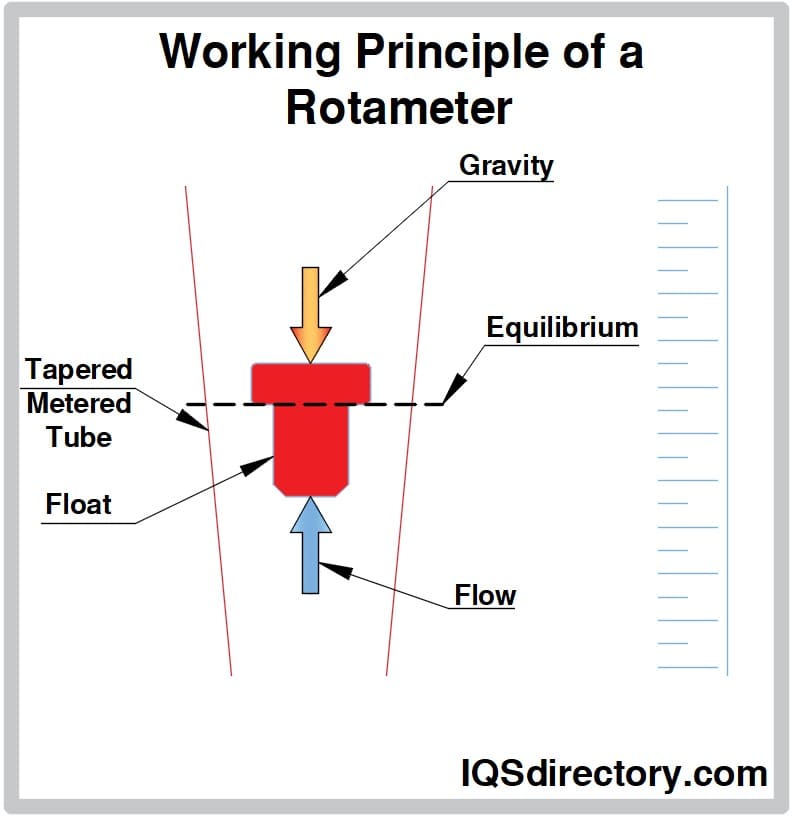

A rotometer is a tapered tube with a float inside. As fluid flows up the tube, it raises a float and increases the area through which the fluid may flow. An increase in the flow raises the float higher until it is suspended in the flow. The level at which the float rises is directly proportional to the flow rate of the fluid. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

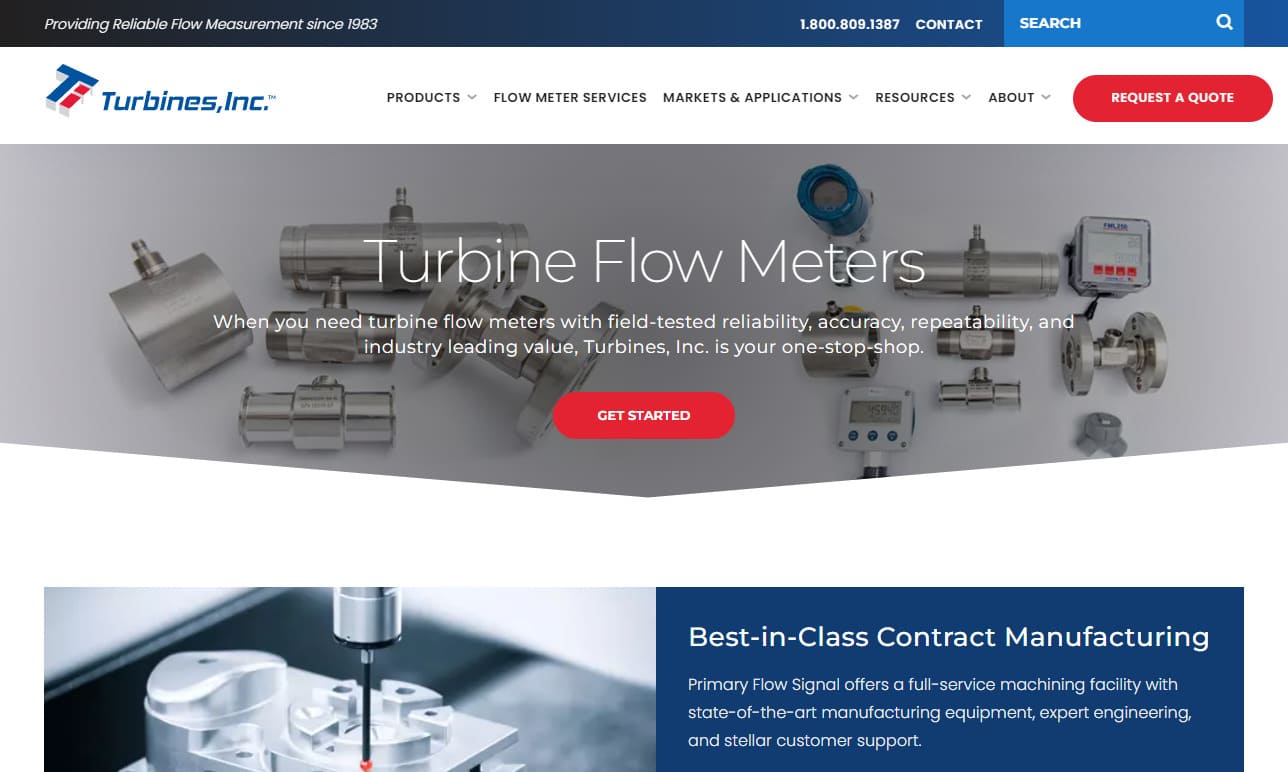

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

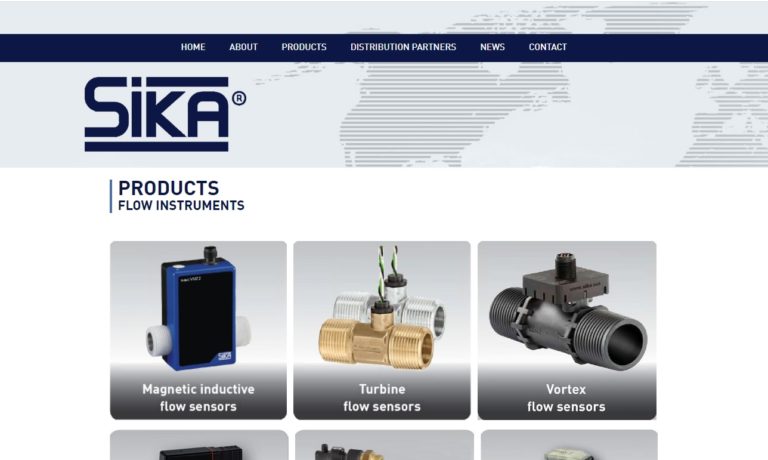

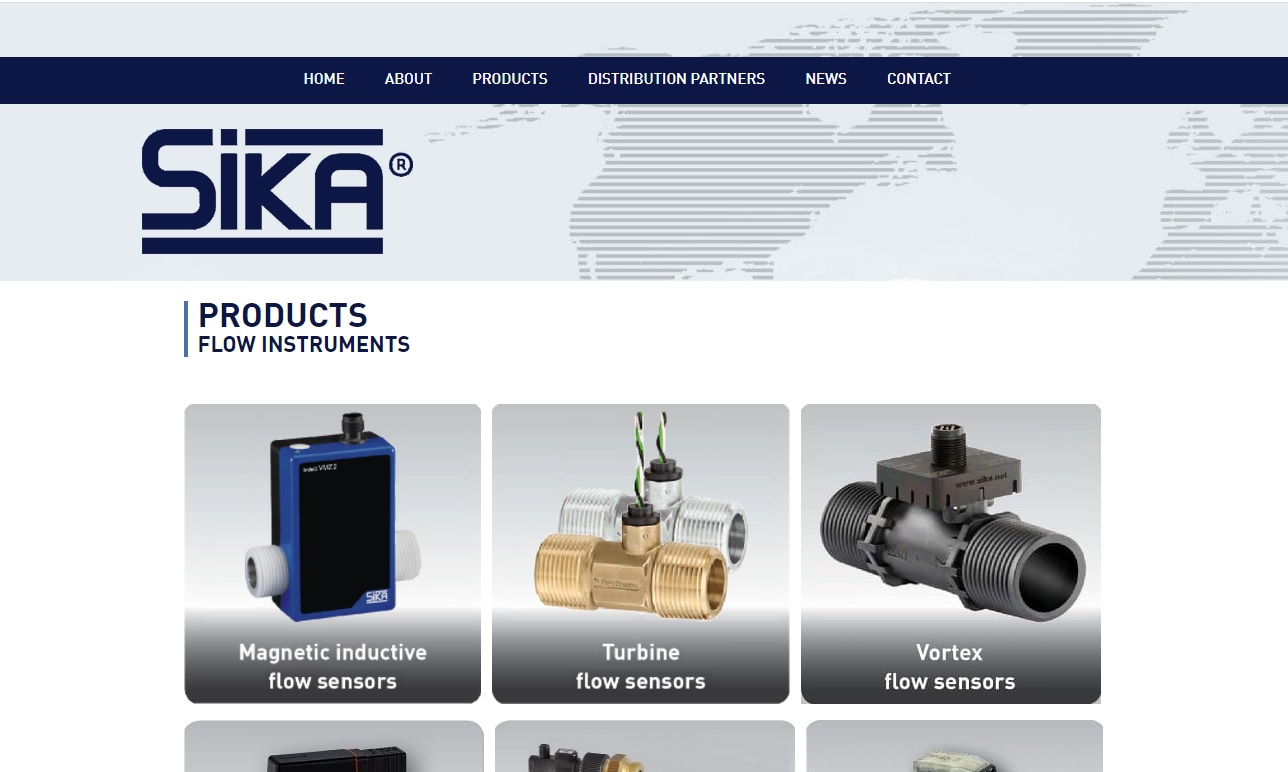

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Rotometer Manufacturers

The principle of a rotometer is based on the variable area where the tapered tube allows the area between the float and the tube, in balanced conditions, to be proportional to the flow rate.

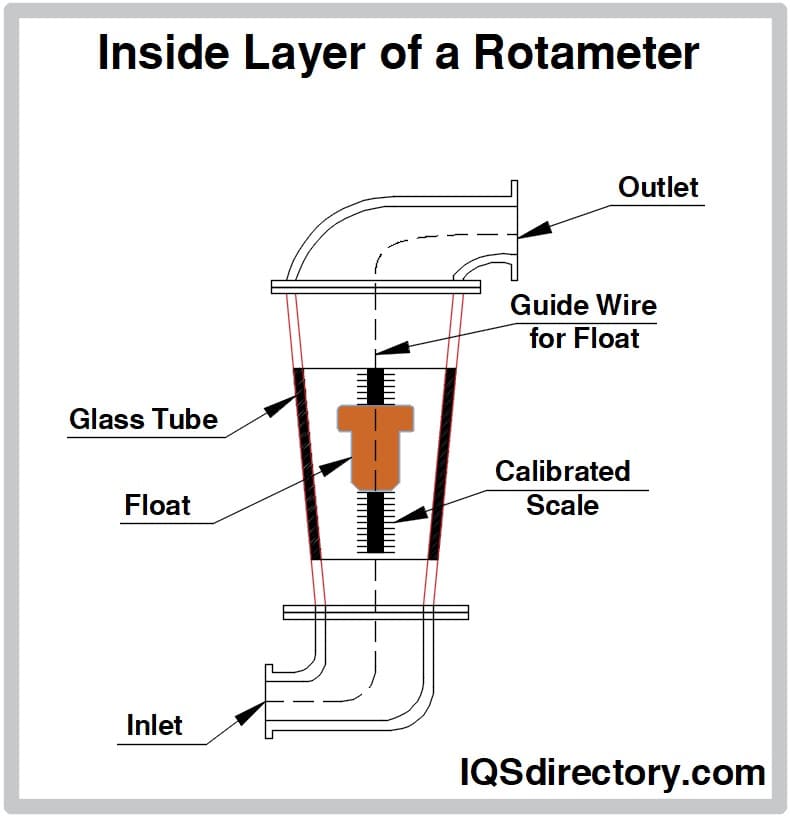

Rotometer Design

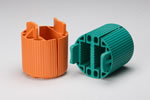

The basic elements of all rotometers are the same and consist of a tube and float. The variations in rotometers are determined by the materials used to make the components and how they are used. Tubes can be made of glass, metal, or plastic with floats of different shapes, sizes, and compositions.

Glass Tubes

Glass tubes are the most common and oldest of the rotometer components. They are made of safety-shielded borosilicate, making them safe for water and air applications. However, there are restrictions regarding the use of glass tube rotometers, which include wet steam and high pH water over 194 °F (90 °C) that can cause the glass to soften. Other substances that must be avoided are caustic soda and hydrofluoric acid, which can etch or dissolve the glass.

Metal Tubes

Metal tube rotometers are used in high temperature and pressure conditions. They are made of stainless steel and use magnetic followers inside the tube to detect the float's position on the outside. There are few restrictions on the use of metal tubes. They can be used with alkalis, hot water, steam, fluorine, slurries, hydrofluoric acid, and molten metals.

Plastic Tubes

Plastic rotometers are used for non-corrosive, low-pressure air, water, and gas flow applications. They are made from various plastics, including polysulfone, perfluoro alkoxy (PFA), or polyamide. Plastic tube rotometers have a clear plastic tube that makes them easy to install and read the scale.

Floats

Floats are made of several materials, including glass, metal, plastic, and Carboloy. To measure the flow of corrosive materials, stainless steel and tantalum are used as floats. Floats can be adapted and designed to fit the needs of any application or fluid. Small floats are made of black glass, stainless steel, and sapphire, while larger floats are made to resist corrosion. The density of floats is adjusted to fit the type of fluid.

How a Rotometer Works

A rotometer is installed vertically with the float at the bottom of the tapered tube, where it blocks the entrance to the tapered end. When the fluid enters the tapered end, the float rises and is moved upwards until the pressure on it equalizes. As the float remains suspended in the fluid, it is positioned in relation to a scale inside the tube. The reading on the scale is the flow rate.

Since metal tubes are not transparent, they are designed with a method for reading the flow rate on the outside of the tube. For this type of rotometer, magnetic followers are placed inside the tube to provide readings on scales placed outside the tube.

Advantages of Rotometers

Rotometers have been widely used for two centuries because of their economical and cost-effective way of measuring flow rate. Over the years, customers have relied on rotometers to provide accurate and precise readings.

- No Power Required – Rotometers are mechanical flow meters that do not need power to measure flow rate. They can be installed in hazardous and remote areas without power.

- Visible Readings – Rotometers make it possible to look at the process flow and assess whether the fluids are in good condition, changing color, or turning dirty or cloudy.

- Cost-Effective – This particular aspect of rotometers is their most attractive feature. Their price and function create savings for a project. Rotometers can be installed with other flow measurement technologies and used to complement those technologies.

- Easy Installation – Rotometers are installed by connecting the process line to the inlet and outlet of the rotometer. They can only be used vertically but are immediately ready once positioned.

- Low Pressure Drop – Multiple rotometers can be installed in an application due to their low pressure drop. This factor means that smaller pumps can be used for a process.

- Repeatability – A key factor related to all flow meters is the necessity of repeatability and consistently supplying the same date. The simple design of rotometers ensures the same results every day, all day.

- Linear Readings – Linear readings mean taking readings is easy, efficient, and uncomplicated.

- Fluid Velocity – Rotometers can measure the flow rate of fluids with a velocity of 1 LPM up to 10 LPM, which makes them suitable for measuring small to medium fluid rates.

Choosing the Correct Rotameter Manufacturer

To ensure you have the most constructive outcome when purchasing rotameters from a rotameter manufacturer, it is important to review several companies using our directory of rotameter manufacturers. Each rotameter manufacturer has a business profile page that highlights their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rotameter business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple rotameter companies with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services