These simple but important flow meters are often called sight flow indicators and are components of industrial process lines that require an instant and inside look of the flow inside the pipe. Unlike ultrasonic flow meters or vortex flow meters, flow indicators do not take calculations or measurements regarding mass or speed. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

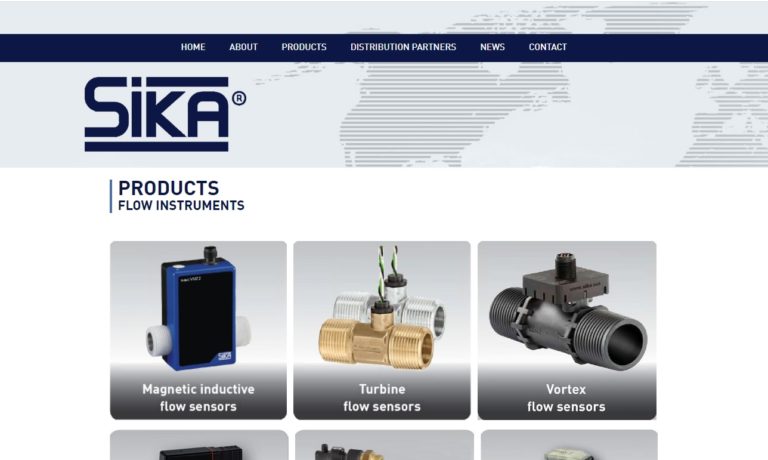

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Flow Indicator Manufacturers

Flow indicators are the type of flow meters that monitor fluid clarity, level, and color through a glass or plastic observation window of varying size. The window can be horizontally or vertically oriented. The body of the flow indicator may be plastic or metal. Double windows held in position by a metal housing and gaskets are used in applications where high-pressure, corrosion, or mechanical impact may be a threat.

Flow indicators are attached to the piping system by threaded, flanged, or butt-welded connection, all of which must be waterproof. For low visibility, flow indicators may contain lights. Visual indicators such as flappers or propellers indicate the direction of the stream although the material type may interfere with such accessories. Flow indicators are used mostly in industrial and manufacturing applications where flowing liquids are part of an important process and need to be monitored.

There are various types of flowmeters and flow indicators that are used depending on the type of liquid and what is being monitored.

Plain sight indicators are the simplest option, containing only an observation window. No moving parts are used, and this type is only for easily visible fluids.

Visual indicators use floating balls, flappers, and propellers. The floating balls indicate the liquid level in hard-to-see applications as an alternative to lights. Flappers are used when the flow of the liquid could be going in two different ways. It lets the observer know the flow direction. Propellers are used for clear or transparent liquids to determine whether or not they are flowing.

Another kind of flow indicator is a drip tube where the liquid drips into the tube in systems with a downward flow.

Some flow indicators have a self-cleaning mechanism consisting of a rotor and wiper. When the observation window is twisted, wipers inside the pipe clean the plastic or glass viewing area to allow for an unobstructed view. The interfering materials on the window are wiped off and carried away with the stream. This method does not require any downtime and is often necessary when the pipes contain suspended solids, slurries or highly viscous materials.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services