One way to understand the way that electromagnetic flow meters work is by considering Faraday’s Law of electromagnetic induction. Faraday’s Law states that, as it moves at right angles through a magnetic field, the voltage produced by a conductor is proportional to its (the conductor’s) velocity. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

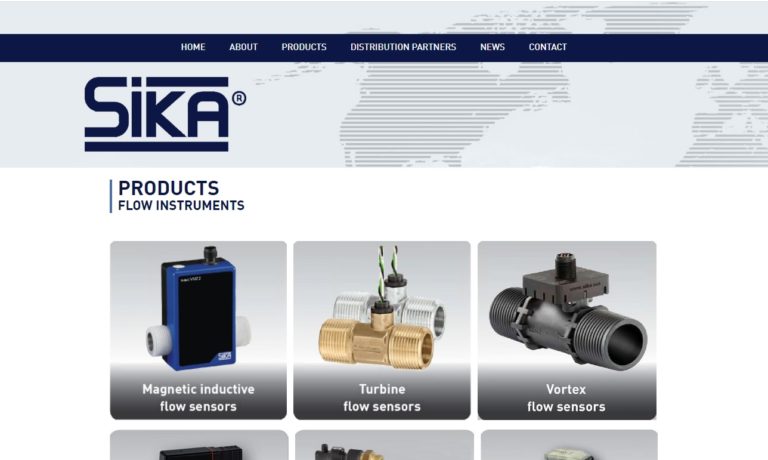

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Electromagnetic Flow Meter Manufacturers

In flow meter terms: electromagnetic flow meters use signal voltage in order to determine velocity, where the flow rate of the conductor is the fluid. For this reason, it is essential that the fluid used with electromagnetic flow meters is conductive and water based. In addition, the pipe in which the fluid flows must have a nonconducting liner. The electrodes must not be allowed to corrode.

These flow meters only work with conductive and water-based fluids. They’re ideal for measuring flow rate of dirty liquids. However, they can work with a wide range of fluids; in fact, they are widely considered the third most common type of flowmeter. This is largely due to the fact that they have no moving parts, which means that they require less maintenance, and tend to last longer.

Because electromagnetic flow meters can only be used with conductive, water-based fluids, before making the decision to purchase one, ask yourself the following questions about your application: Does my application used conductive fluid? Is my application fluid abrasive? What is the minimum and maximum flow rate of my application? Is my pipe always full?

Even if you ask yourself all the right questions, the only way to know without a doubt that this type of flow meter is right for you is by talking over your application with an experienced flow meter manufacturer. In fact, a good manufacturer, like one of those we have listed on this site, will be able to provide you with a custom flow meter, if you wish.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services