A rotameter is a flow meter that measures the flow of liquids, gasses, and steam using a float placed inside a conical tube where the space between the float and the tube is larger at the top of the float to allow more flow. Placed in a vertical position, a rotameter uses gravity and pressure to move the float up or down to supply a flow reading. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

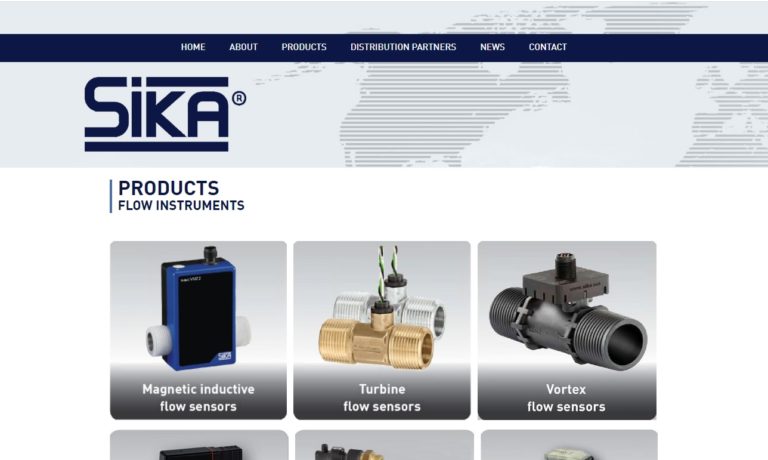

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Rotameter Manufacturers

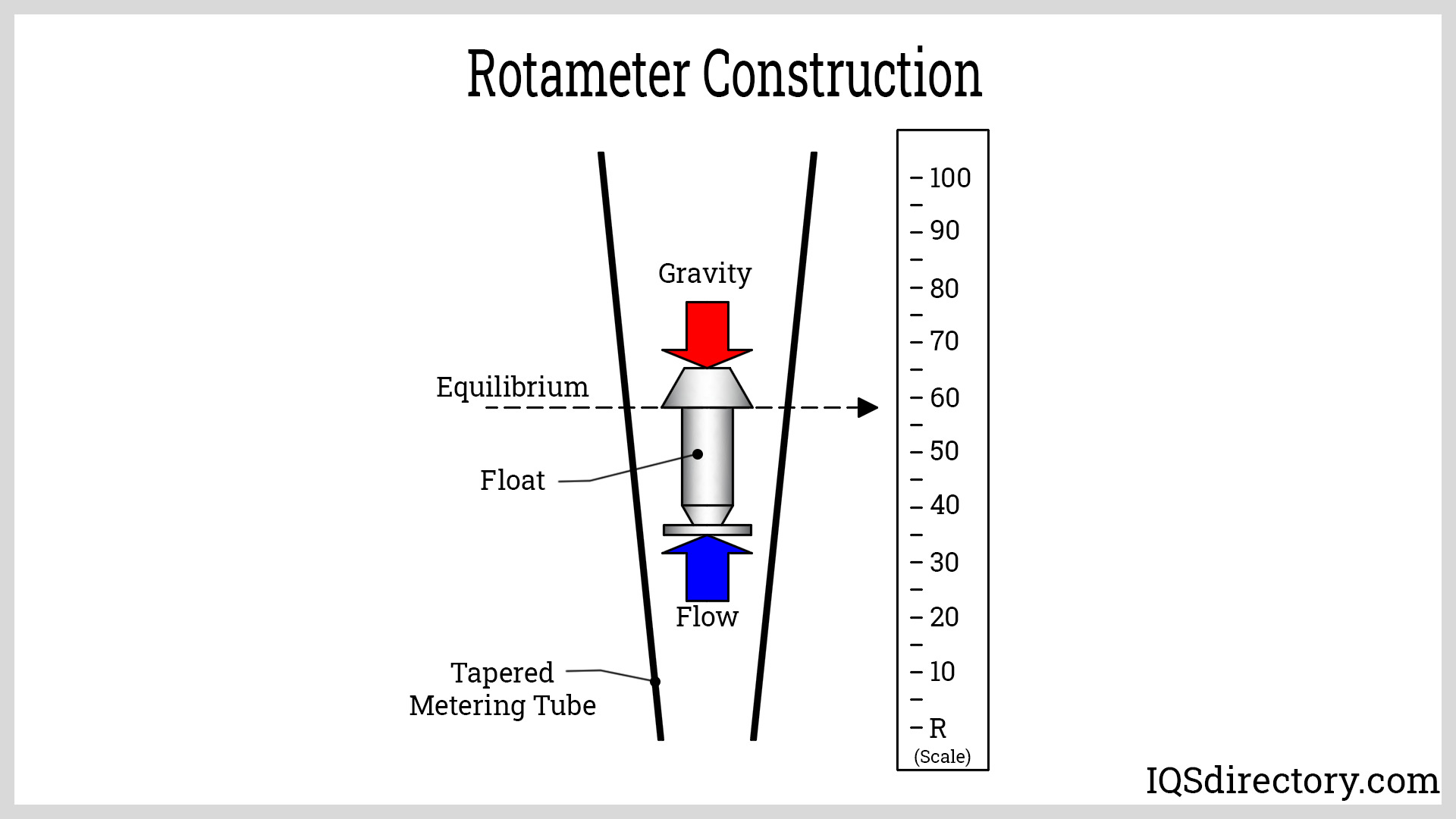

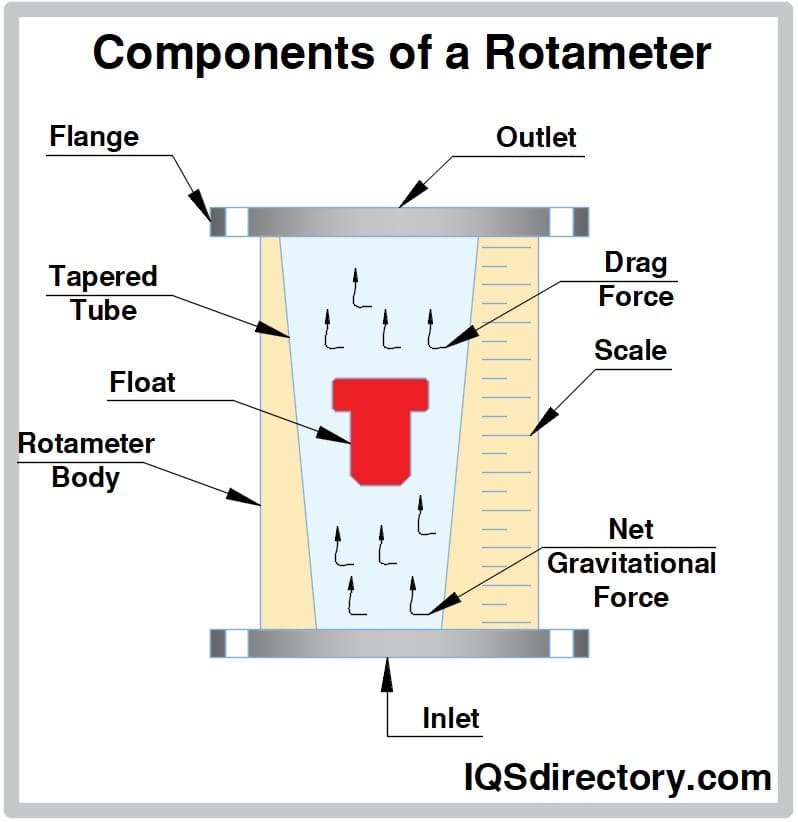

The material to be measured enters at the small bottom end of the tube and flows upward over the float and exits out the top.

When there is no flow through the meter, the float rests at the bottom of the tube where the diameter of the float is the same as the diameter of the tube. As fluid enters the tube, the float moves up or down in proportion to the flow rate. When the float reaches a stable position, the forces in the tube are in equilibrium.

How a Rotameter Works

When a fluid is flowing through a rotameter from the bottom to the top, it experiences two forces, which are gravitational downward force and upward drag force. The flow pushes the float up against the gravitational force. Eventually, when the force being applied matches the weight of the float, the float will reach equilibrium. Once the float weight and gravity are stable, the distance upward that the float travels is equal to the velocity of the flow.

The tube of a rotameter is a transparent conical shape, which is helpful in observing the flow and measurements. The float indicates the rate of the flow on a scale that is located next to the rotameter tube. For more precision measurement, transmitters are used for recording the flow rate that are connected to the tube and float.

The scale of a rotameter is linear in equal scale increments, the area of which is proportional to volume of the flowing material with an accuracy of ±2%. One of the names for a rotameter is variable area flow meter, a name that is given in regard to the shape of the tube that has a smaller diameter at the bottom than at the top. The tapered design creates an increase in volume capacity in the tube that is read as an accurate measurement.

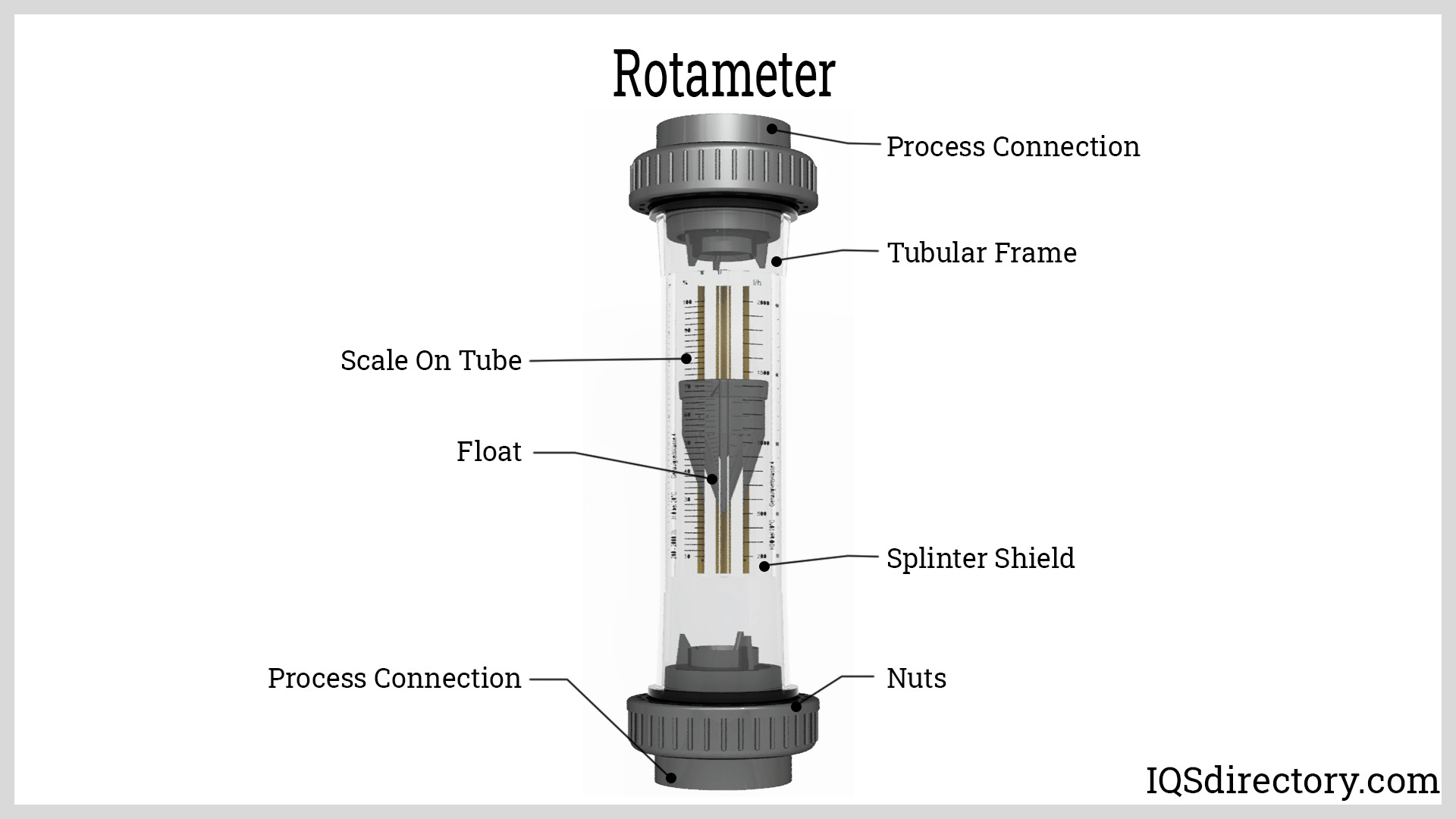

Parts of a Rotameter

The parts of a rotameter are the metering tube, float, and scale. How the three parts are designed determines the difference between rotameters. The scales, floats, and tubes are made of a variety of materials with tubes being made of glass, plastic, or metal.

Additionally, transmitters can be added to a rotameter to avoid the need for manual readings and provide an increase in accuracy.

Metering Tube

The metering tube holds the float and is made of glass, plastic, or metal, with glass tubes being standard since they are the easiest to see through. The choice of the type of tube material varies in accordance with the type of material being measured. Glass is mainly chosen due to its ability to withstand the effects of corrosive substances. When measuring less caustic materials, plastic is preferred since it is less expensive but just as durable. Metal tubes are used with opaque fluids and liquids where the ability to see the flow is impossible, and there is higher temperature and pressure.

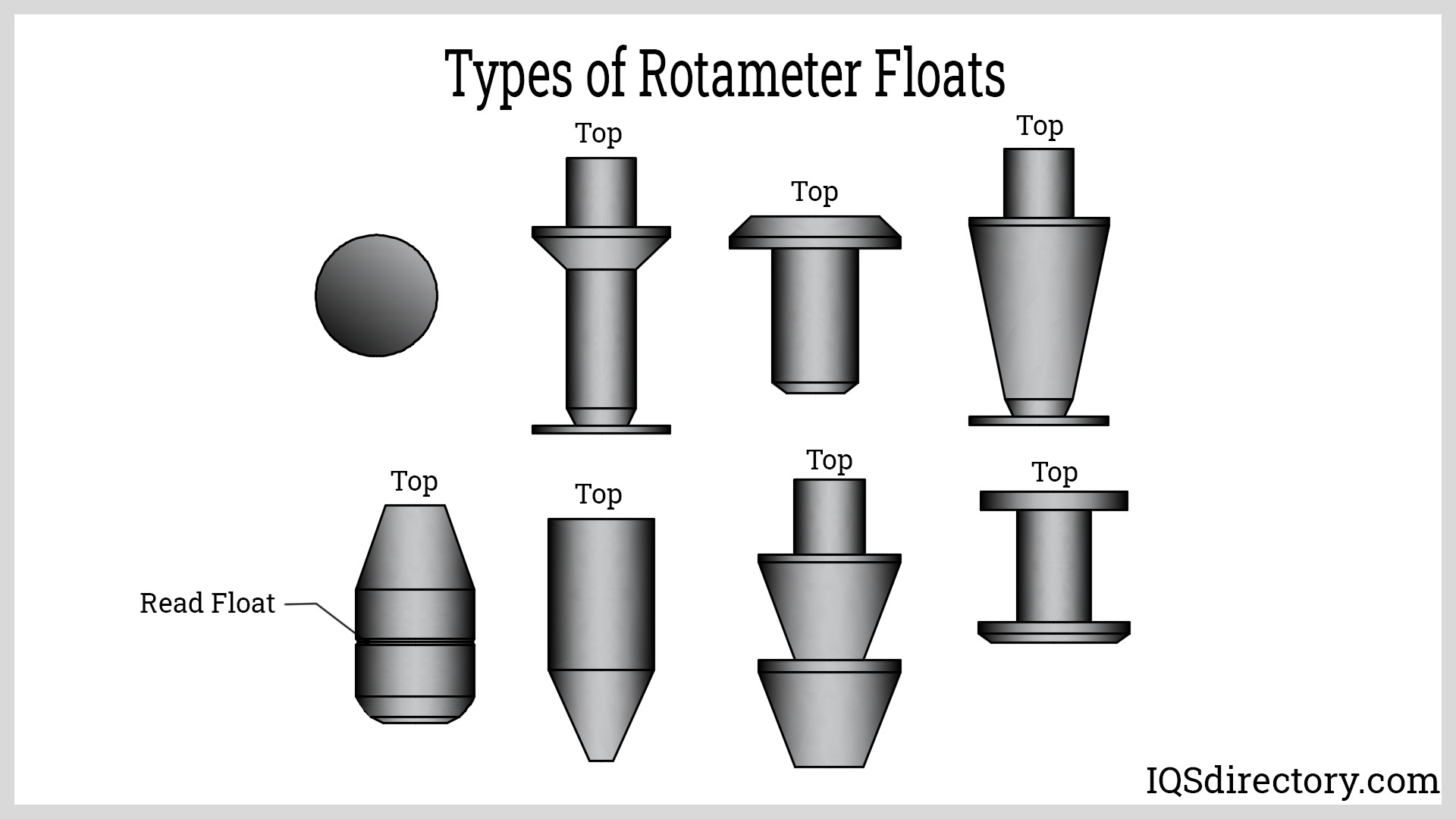

Floats

Floats are available in a wide range of shapes based on the accuracy requirements and the types of materials being measured. The design of the float and its materials extend the flow range of a rotameter. The simplest type of float, a ball, has different flow ranges depending on the diameter of the ball.

The materials used to make floats varies according to the materials being measured by a rotameter. Smaller floats are made of glass, stainless steel, or tantalum, while larger floats are made from strong, durable materials to be able to withstand more aggressive and caustic materials. The density of the float changes the range of a rotameter.

Scale

The scale is attached to the side of the rotameter and is read like a thermometer. Scales are calibrated according to the traits of the fluid, gas, or steam being measured. They show the flow measurement as displayed by the float. The scale is linear because the flow rate is determined by area variation. Readings are accurate through their complete range.

As the material in a flow changes, the scale of a rotameter needs to be recalibrated to meet the parameters of the new material. The traits of materials change in heat, pressure, viscosity, and humidity, factors that can change rotameter readings. Consistency in these factors and proper calibration ensures the accuracy of the final readings.

Types of Rotameters

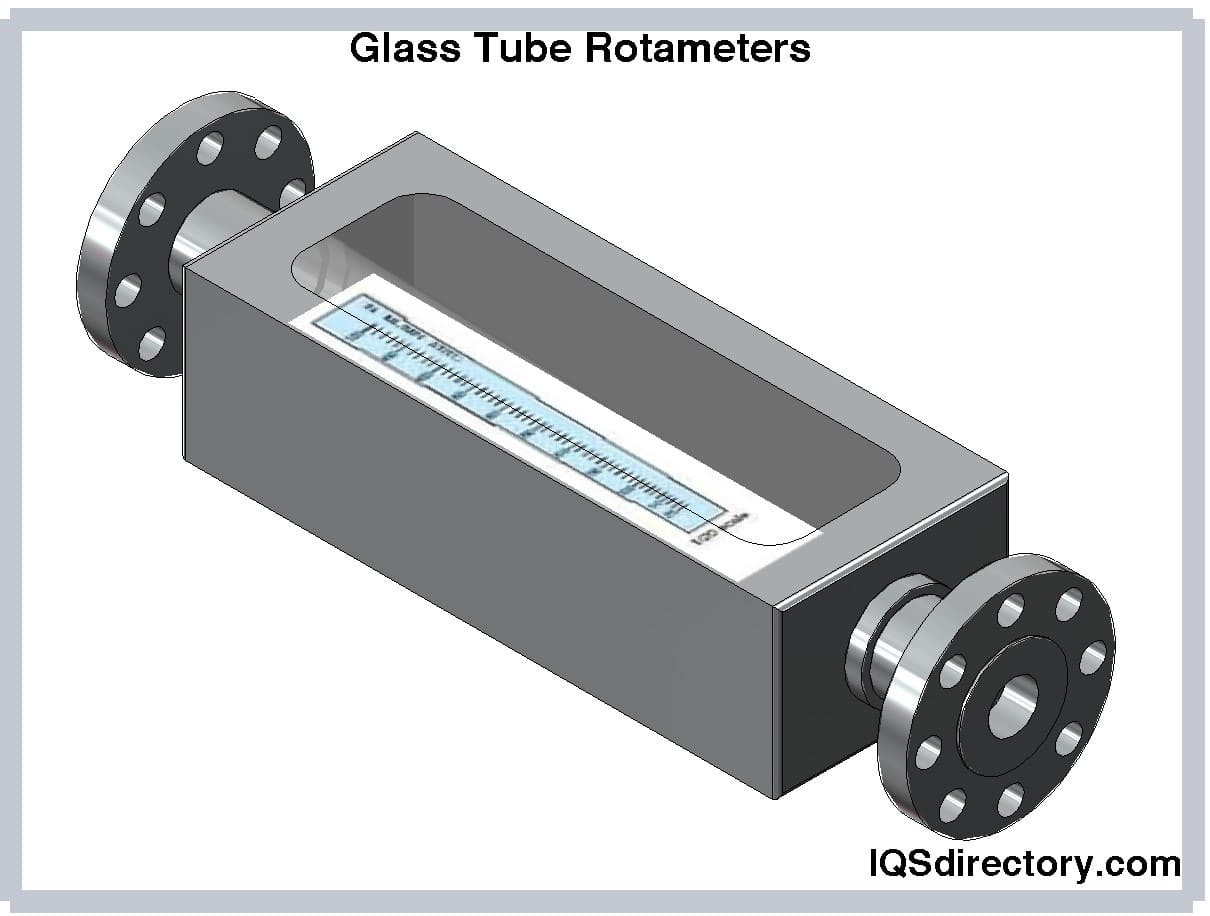

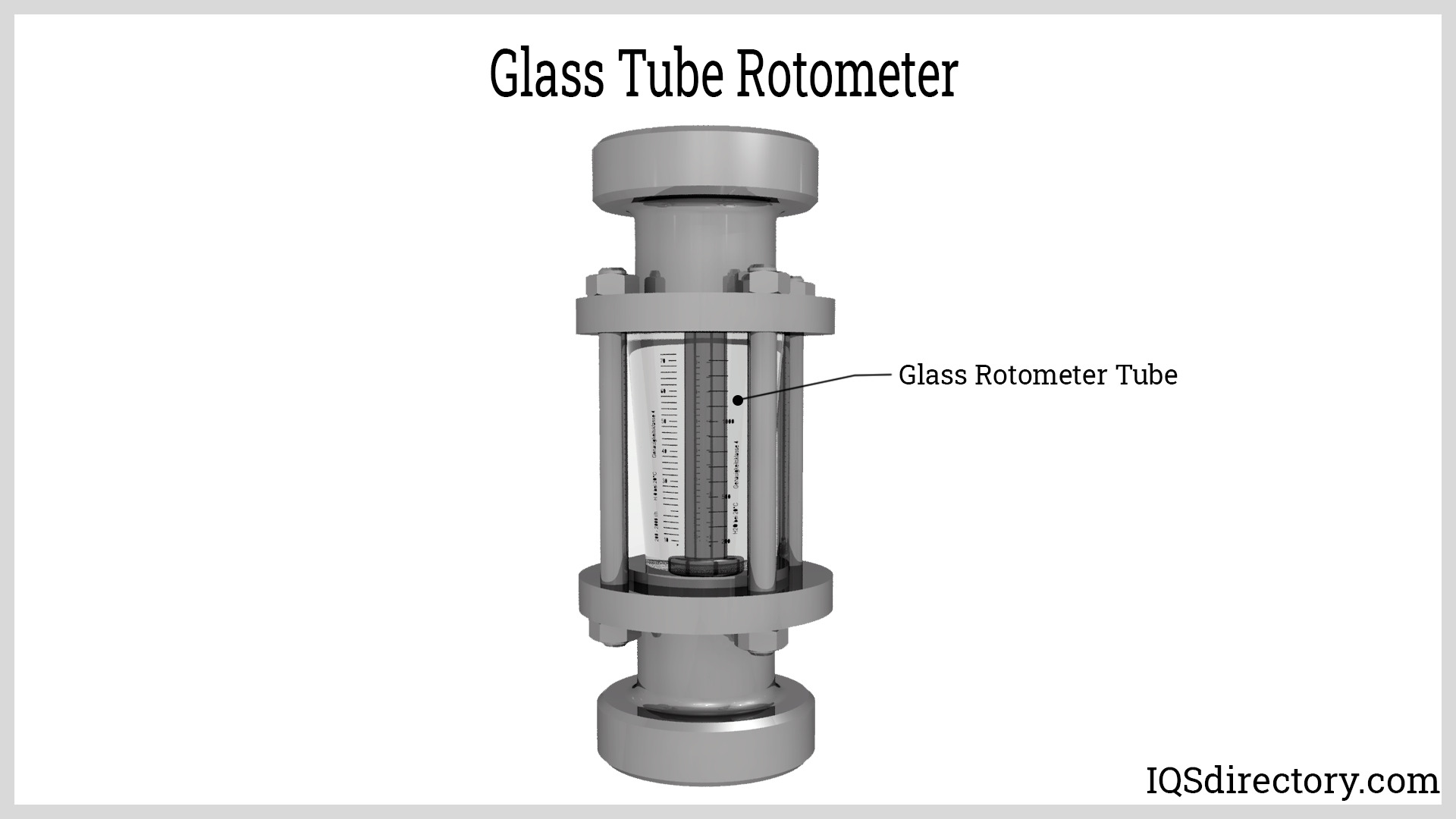

The first rotameter was introduced in 1908 and has slowly been changed and improved over the years with new types of floats, different tube shapes, and the use of various plastics. The popularity of rotameters is due to their simple design, reliability, and low cost. Three common types of rotameters are glass, flanged, and armored.

Glass Rotameter

Glass rotameters are widely used for several applications. They are accurate at measuring liquid or gas flows with high pressure and temperature for a wide range of flow rates. Glass rotameters are resistant to thermal shock, pressure, and oxidation due to being constructed of borosilicate glass that can withstand 200 psi or 13.8 bar of pressure.

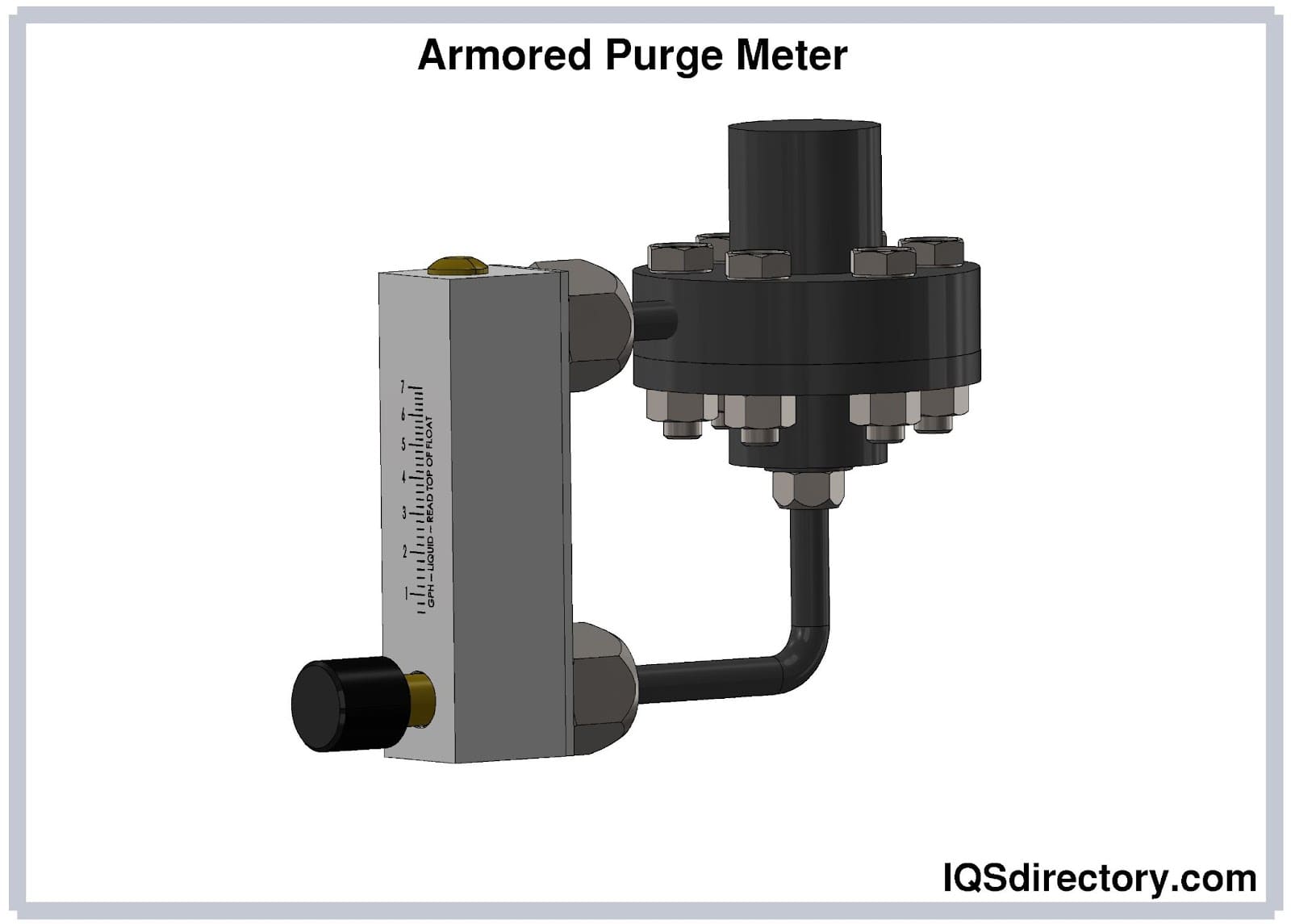

Armored Purgemeter Rotameter

Armored purgemeter rotameters are capable of clearing liquid from the system if conditions are not correct. They are used for high pressure, corrosive, and low flow rate applications. Armored purgemeter rotameters are ideal for use with cloudy and opaque fluids.

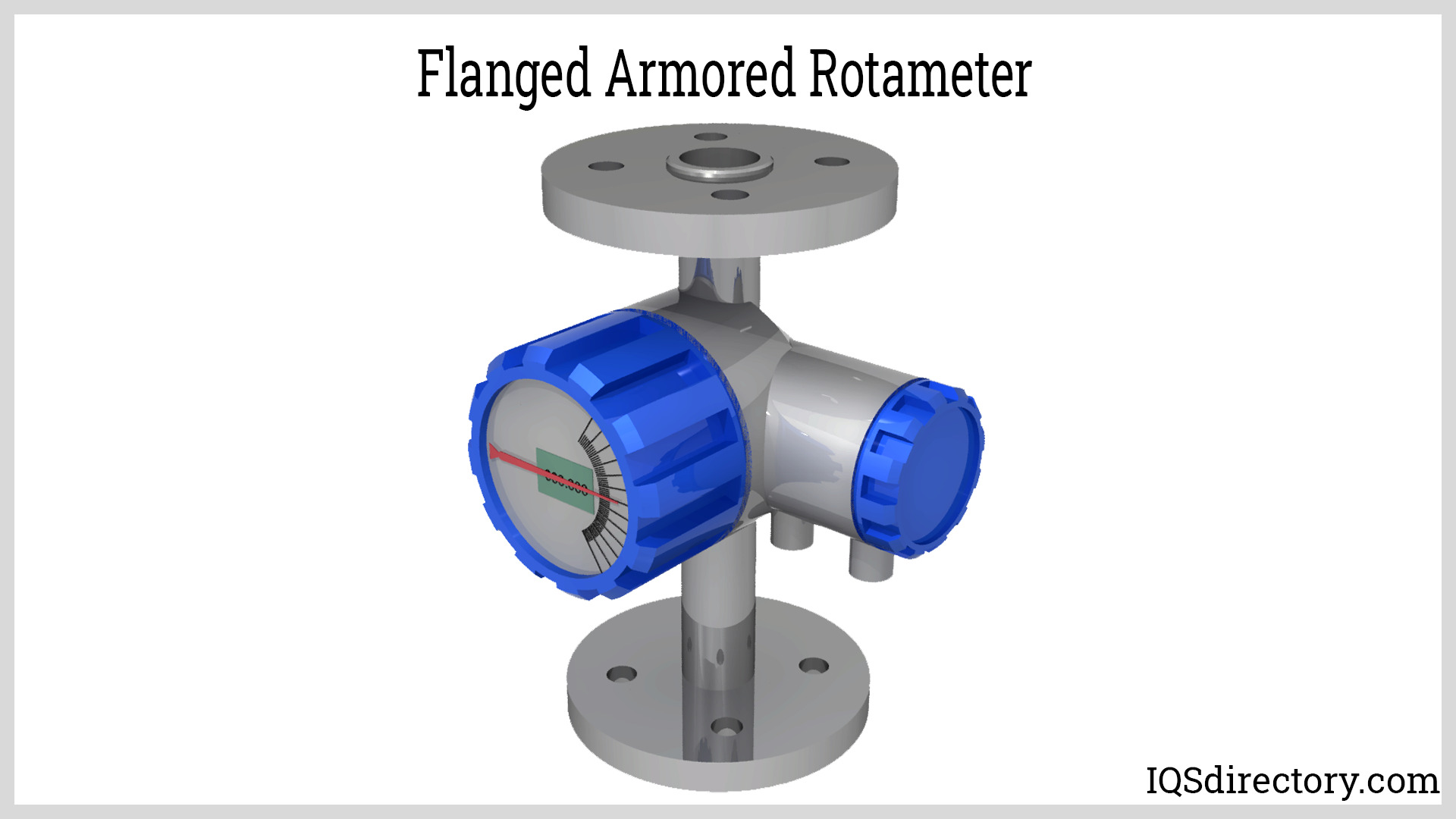

Flanged Armored Rotameter

Flanged armored rotameters are used in high pressure applications where fluids or gasses are very aggressive and opaque. They are used with automated systems in petrochemical factories, chemical production, and the pharmaceutical industry. Flanged armored rotameters are used with transmitters, alarms, HART communications, and digital displays.

For over 100 years, rotameters have been used as flow meters for a wide variety of applications. Their low cost, accuracy, simple construction, and ease of use makes them an ideal tool for measuring flow velocity.

Choosing the Proper Rotameter Supplier

To ensure you have the most positive outcome when purchasing rotameters from a rotameter supplier, it is important to compare several companies using our directory of rotameter suppliers. Each rotameter supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each rotameter business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple rotameter companies with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services