Hydraulic flow meters measure the linear, nonlinear, mass, and volumetric flow rate of hydraulic fluids. The three parts of a hydraulic flow meter are the device, transducer, and transmitter. The transducer senses the movement of the hydraulic fluid, while the transmitter produces a flow signal from the transducer’s sensed signal. The calculation of the volume and flow is based on the concept that the passing fluid volume is proportional to the cross-sectional area and the fluid velocity. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

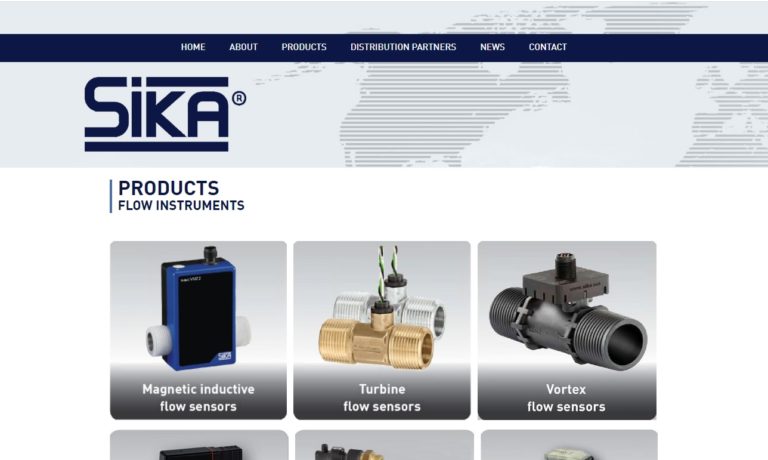

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Hydraulic Flow Meter Manufacturers

What is Flow?

Measuring flow is essential to perfecting and improving the efficiency of a process and is a part of the dynamics and mechanics of fluids. It involves the movement of fluids subjected to unbalanced forces, which continue the motion of fluids as long as they remain unbalanced. Fluids measured by hydraulic flow meters are incompressible, meaning their density does not change when an external force is applied.

Flow is the measurement of the volume of a fluid as it passes a fixed point at an established unit of time. For hydraulic applications, flow is calculated in liters or gallons per minute. Fluid flow is the foundation of hydraulic systems and must be monitored carefully since hydraulic fluids transfer energy from one part of the system to another.

Functions of Hydraulic Fluids

Since not all hydraulic systems are the same, their fluids are chosen following the needs of an application. The properties of hydraulic fluids include viscosity, lubrication, demulsibility (the ability to release water), and chemical and environmental stability. Hydraulic fluids have five functions:

Power Generation

In a hydraulic system, the incompressible fluid transfers energy from one point to another to generate power. The pump initiates fluid flow, and pressure develops at the point of restriction.

Contaminants

One of the primary functions of hydraulic fluid is to remove contaminants, which can damage the system or reduce its productivity. The flow of hydraulic fluid removes any forms of foreign particles by moving them to the filtration system.

Lubrication

The constant movement of the various components of a hydraulic system creates friction that can cause wear and failure. The smooth flow of hydraulic fluids reduces friction by creating a lubricating film.

Sealing the System

Because all hydraulic systems operate under pressure, each system must have a tight seal. The proper hydraulic fluid forms an additional seal between mechanical parts.

Heat Transfer

The friction of hydraulic components produces heat that has to be cooled. The smooth and controlled flow of hydraulic fluids carries away any generated heat.

Types of Hydraulic Flow Meters

The selection of a hydraulic flow meter is a critical aspect of a system's function since an incorrect choice can lead to errors in diagnosis. The factors to be examined when making the selection are fluid properties, operating condition of the system, flow measurement, accuracy, effect of the flow meter on the fluid and vice versa, and cost. As with all flow meters, there are several types of hydraulic flow meters to choose from, with each type designed to perform with a certain type of hydraulic fluid.

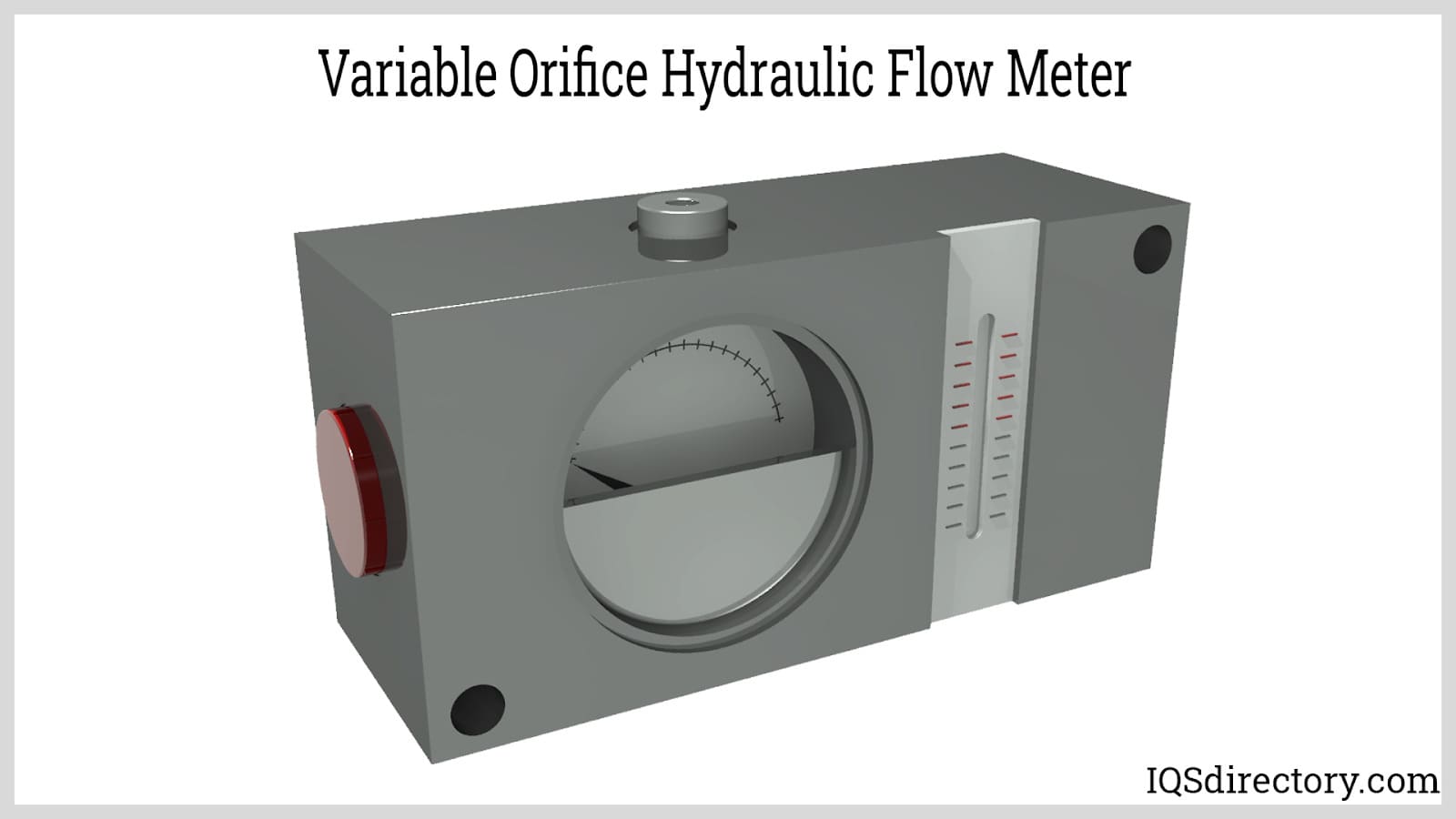

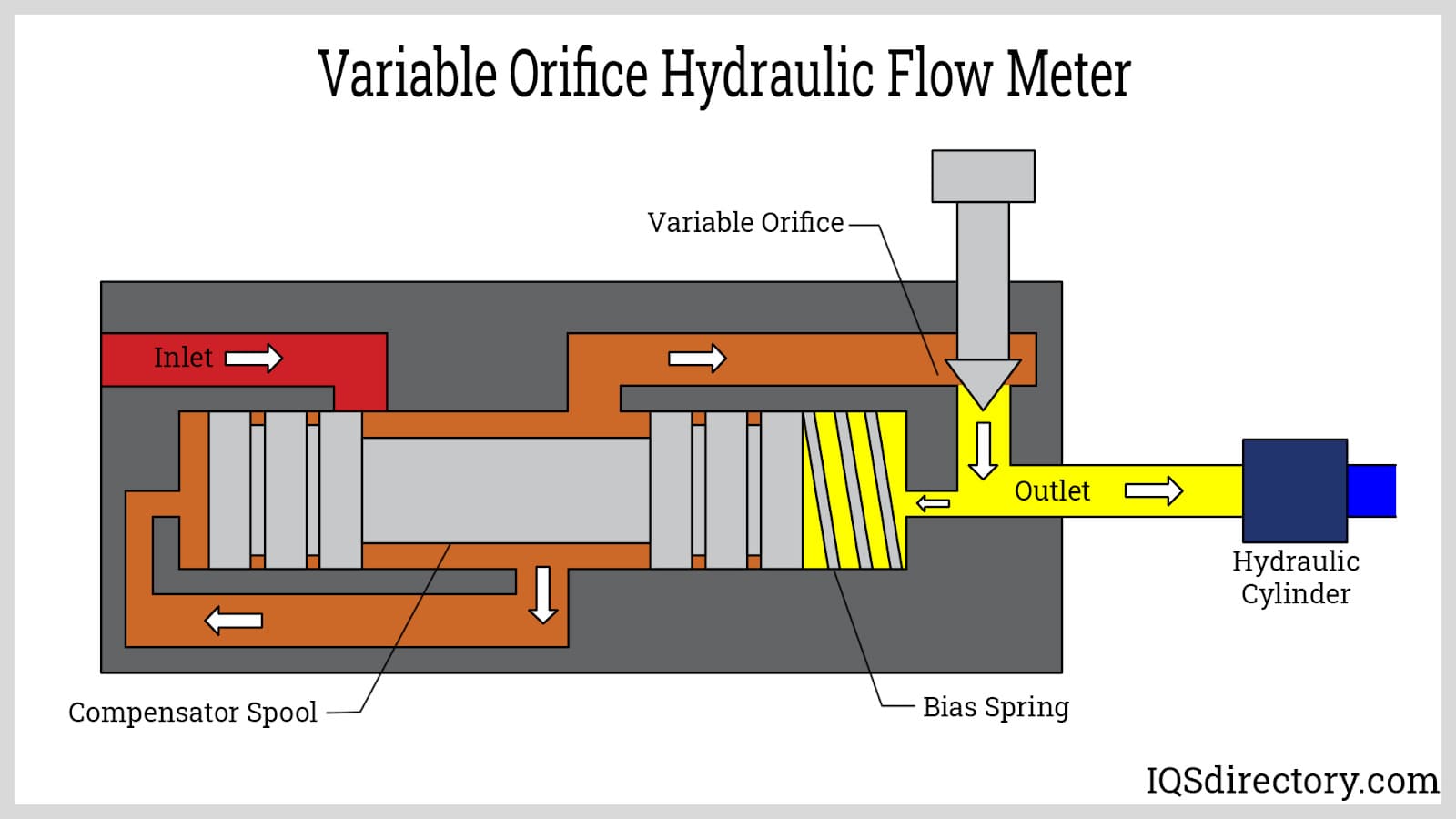

Variable Orifice Flow Meter

A variable orifice hydraulic flow meter has a piston or ring connected to a spring. The force of the fluid displaces the piston or ring, which increases the size of the flow meter's orifice. The flow rate is indicated on an analog readout connected by a magnet to the piston or ring.

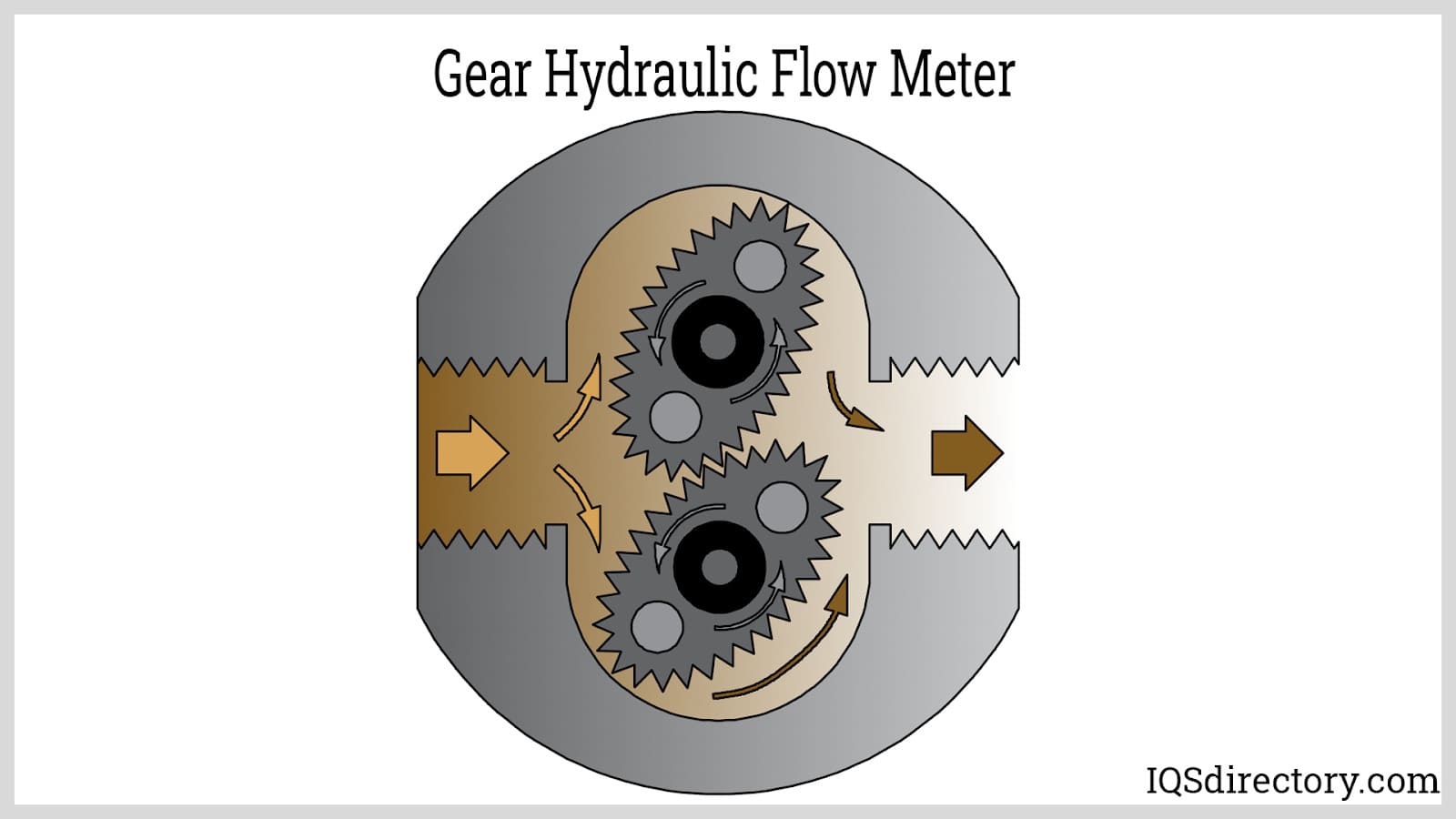

Gear Flow Meter

Gear type hydraulic flow meters are types of positive displacement flow meters that look like gear motors with intermeshed, rotating gears. The fluid flow rotates the gears, one of which is connected to the transducer. An increase or decrease in the fluid flow causes the gears to rotate faster or slower, providing the flow rate reading. More accurate gear type hydraulic flow meters have two transducers that measure direction and improve resolution.

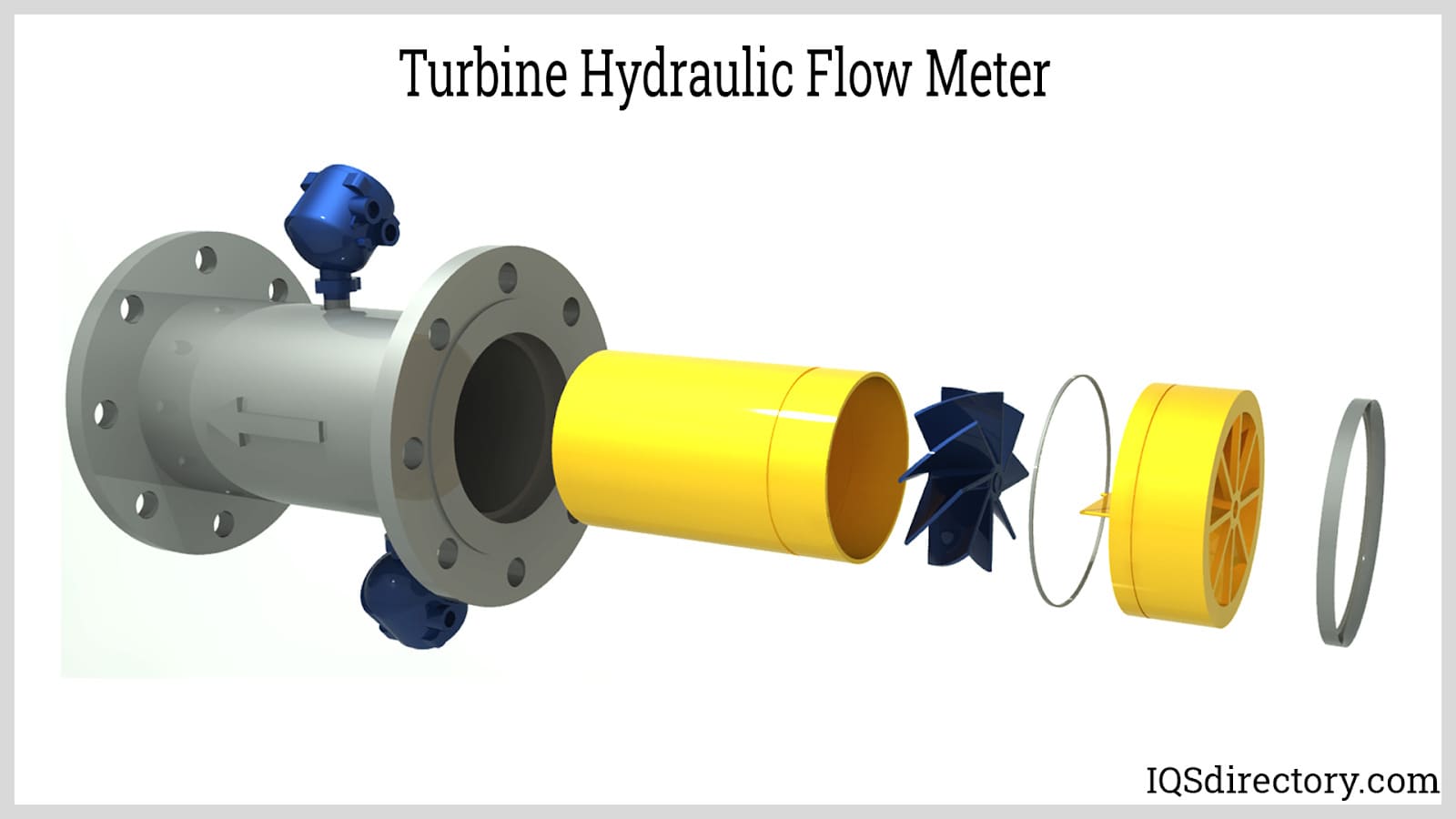

Turbine Flow Meter

Turbine hydraulic flow meters are a very common type of mechanical flow meter. The turbine rotor is placed in a shaft between flow straighteners, and the flow of the hydraulic fluid turns the turbines. The transducer, connected to the turbine rotors, senses the movement of the blades, which is the flow rate.

Choosing the Correct Hydraulic Flow Meter Manufacturer

To ensure the most constructive outcome when purchasing hydraulic flow meters from a hydraulic flow meter manufacturer, it is important to compare several companies using our directory of hydraulic flow meter manufacturers. Each hydraulic flow meter manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each hydraulic flow meter company website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple hydraulic flow meter businesses with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services