This flow meter type is popular in industries such as: food and beverage, pharmaceuticals, wastewater management and water treatment, pulp and paper, power, HVAC, and mining. Within these industries and others, they are often used to measure the flow of dirty and highly hazardous or corrosive fluids. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

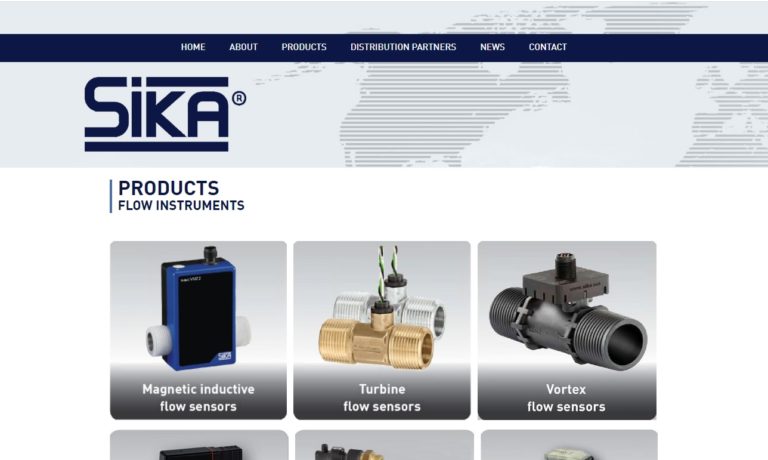

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Clamp-On Flow Meter Manufacturers

They are so useful for these types of applications because, since they do not actually come in contact with the fluids, the flow meter sensor heads are not at risk for damage like corrosion.

Instead of reading flow from inside the pipe, they read flow from the outside of the pipe, the surface to which they are clamped. There, the flow meter sensor(s) collect flow data by sending and receiving ultrasonic pulses. They send their collected data to a connected readout for interpretation. Typically, this readout device is digital, but it can also use analog outputs, relay outputs, binary + RTD inputs, or a combination of all of them.

Most often, these highly useful flow meters come in single and dual-sensor models. Single sensor meters work using piezoelectric transmit and receive crystals that are planted in just one sensor body. Customers clamp these onto a single point on the pipe surface and connect the sensor to the pipe using a coupling compound. Dual-sensor meters are built with the transmit crystal in one sensor body and the receive crystal in the other.

The main drawback of clamp-on flow meters is the fact that they do not work well with pipes that are lined, particularly linings of copper, concrete, plastic or fiberglass. This is because the lining interferes with transmit and receive signals, making the flow meter readings inaccurate.

Nevertheless, the unique, non-invasive nature of clamp-on flow meters presents a variety of benefits. First, the monitored flow remains undisturbed and without pressure drops. This allows for undistorted, more accurate readings. In addition, during installation, it is not necessary to break open your pipe system in order to insert the flow meter. Rather, you can easily install and uninstall the meter by clamping on to your pipe. This not only saves you time and money, but also makes it less likely that your system will leak or become contaminated. Also, because your meter will not be exposed to fluids, it will last longer. This is cost-effective both in the short and the long run; if you like, when you’re done with one application, you can remove your meter from the pipe and use it on another.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services