There are a variety of different ways to categorize flow meters and fluid flow measurements. The two main flow meter categories are volumetric and mass flow meters, which separate flow meters based on whether they measure flow as a volume per unit time or a mass per unit time. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

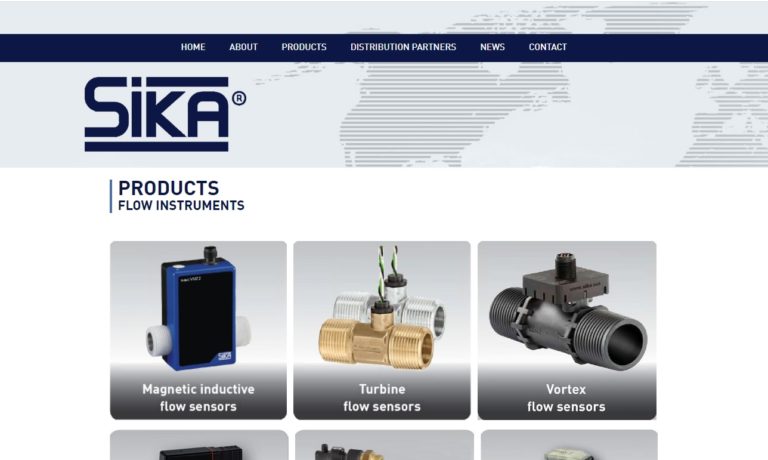

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Turbine Flow Meter Manufacturers

The categories can be broken down further depending on the construction of the meter and the method used to make the measurement. These categories include pressure-based meters, mechanical flow meters, optical flow meters, and many others. Turbine flow meters fall into the volumetric flow meter and mechanical flow meter categories.

The main component of the turbine flow meter is, naturally, the axial turbine. The turbine is typically located at the center of the pipe with its axis aligned with the axis of the pipe. As a liquid or gas passes through the pipeline, it comes in contact with the turbine and imparts some of its energy on the blades of the turbine. The force of the fluid on the turbine blades causes the turbine to spin, and the speed at which the turbine spins can be used to determine the flow rate of the liquid or gas.

Faster flowing fluids exert greater forces on the turbine blades and thus cause the turbine to spin faster, and slower moving fluids impart less energy on the turbine, causing the turbine to spin slower. This relationship between flow rate and turbine speed can be expressed using a formula, which is used to accurately calculate the fluid flow rate.

Flow meter turbines can be manufactured from a variety of different materials to better fit the needs of specific applications. Plastics and non-corrosive metal alloys are popular materials for use with corrosive and volatile fluids, as they drastically improve the turbines longevity and performance.

Due to the mechanical nature of the meter, an upstream filter is essential, especially for use in applications involving inhomogeneous fluids. The filter helps catch debris and impurities that could reduce the quality of the fluid product and helps prevent damage to the turbine.

Turbine flow meters are used across a broad spectrum of industries and are used in applications ranging from water distribution to fire protection. Large commercial users and water utilities take advantage of these flow meters because they are affordable, easy to use, and provide accurate flow rate measurements. Additionally, the fire protection industry utilizes specialized turbine flow meters that are temporarily installed to meter the water used from fire hydrants.

While these flow meters are very accessible and effective, they do have limitations. Compared to other non-mechanical flow meters, maintenance is a much greater issue with turbine flow meters. Filters can become clogged from an abundance of debris or impurities, and turbines can be damaged from prolonged use. Careful attention should be given to maintaining the meter to ensure that it continues to provide accurate measurements.

The accuracy of turbine flow meters is also heavily dependent on the fluid flow, becoming inaccurate with lower flow rates. However, with the proper precautions and understanding of your applications, a turbine flow meter is an exceptional option for your flow metering needs.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services