For the most part, flowmeters are used to infer mass flow through calculations that flowmeters and flow monitor instruments make after taking various flow measurements, such as absolute pressure, differential pressure, viscosity, and temperature. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

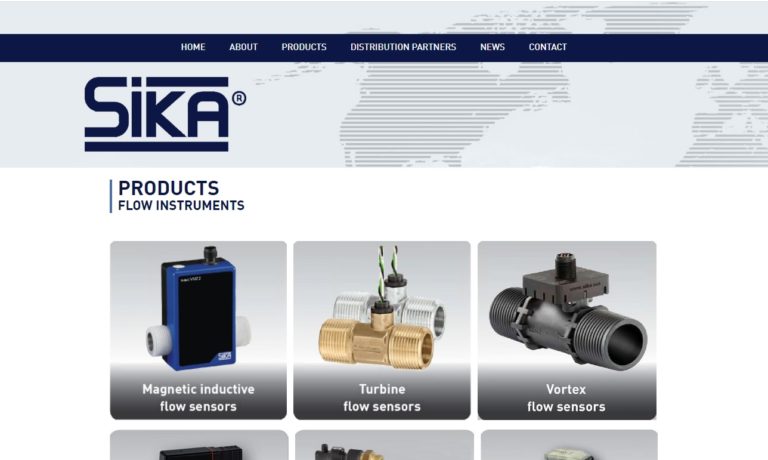

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

More Flowmeter Manufacturers

Most flowmeters are made of three parts: the primary device, transducer, and transmitter. These three flowmeters parts are usually combined so that the flow meter is one complete instrument. Flow indicators, which are observation windows in industrial processing lines, aid in measuring flow by visual indicators.

Flowmeters are useful in a variety of fields. Medically, flowmeters are can be used measure a patient's air intake. In plumbing, flowmeters are used to measure the amount of fluid running through a tube for efficiency purposes. In general, flowmeters are used in many industrial applications for flow measurements to help companies determine profit gain or loss. Other industries that benefit from the use of flowmeters include automotive, petroleum and gas, utility services, HVAC, food processing, and raw materials.

Flowmeter manufacturers offer various instruments for different measurements of flow.

Thermal mass flow meters take measurements with two sensors that work together. A temperature sensor reference and an active heated sensor take measurements by calculating how much heat loss occurs in the flowing liquid, and thus these flowmeters can determine the flow rate based on this amount.

Another type of flowmeter is the Coriolis mass flow meter, which operates on the basis of the Coriolis Effect. In the Coriolis Effect, an excitation force is applied to the flowmeter tube, causing the fluid or gas to rotate because the acceleration is acting in opposite directions on both sides of the applied force. A flowmeter measurement can then be taken.

Other kinds of flowmeters operate using sound. These are called ultrasonic flowmeters, and include several types, like Doppler Effect flow meters and time-of-flight flowmeters.

Each type of flowmeter has specific guidelines that must be followed for proper use. For example, when using gas flowmeters, the flowmeters must remain full of gas. Liquid in gas flowmeters can affect the flowmeter's accuracy. Similarly, in order for liquid flowmeters to work properly, they must remain full of liquid. Gas in liquid flowmeters can affect the accuracy of the flow meter's readings, as can contaminants of any kind.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services