Venturi flow meters are based on the concept of the Venturi effect, which states that a reduction in fluid pressure occurs when a fluid flows through a constricted section of a pipe. The fluid’s velocity increases as it passes through the constriction, following the principle of the conservation of mechanical energy. The amount of energy accumulated by the increased velocity is balanced by a drop in pressure. A measurement of the change in pressure provides the flow rate of the fluid. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

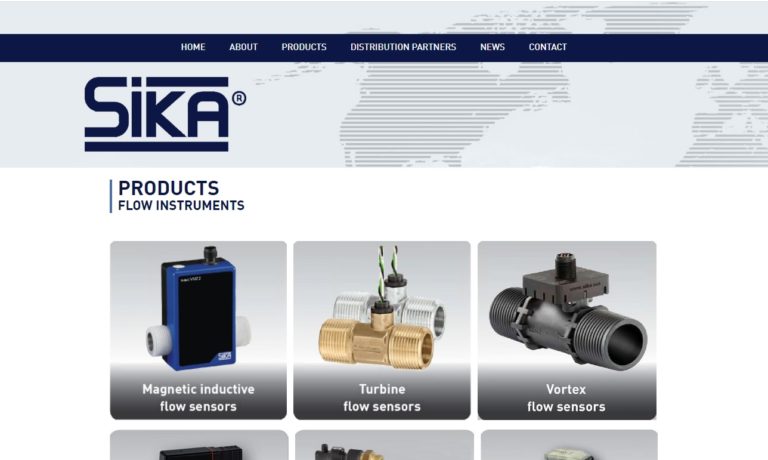

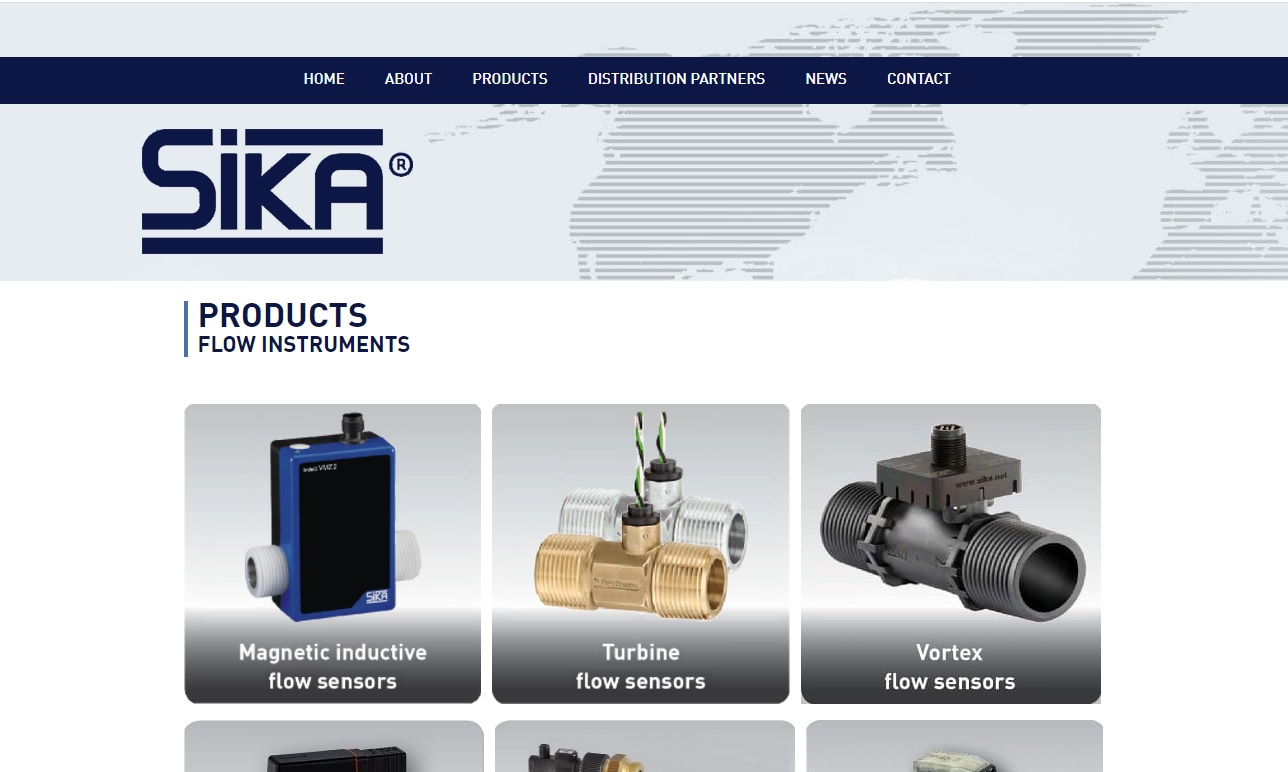

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

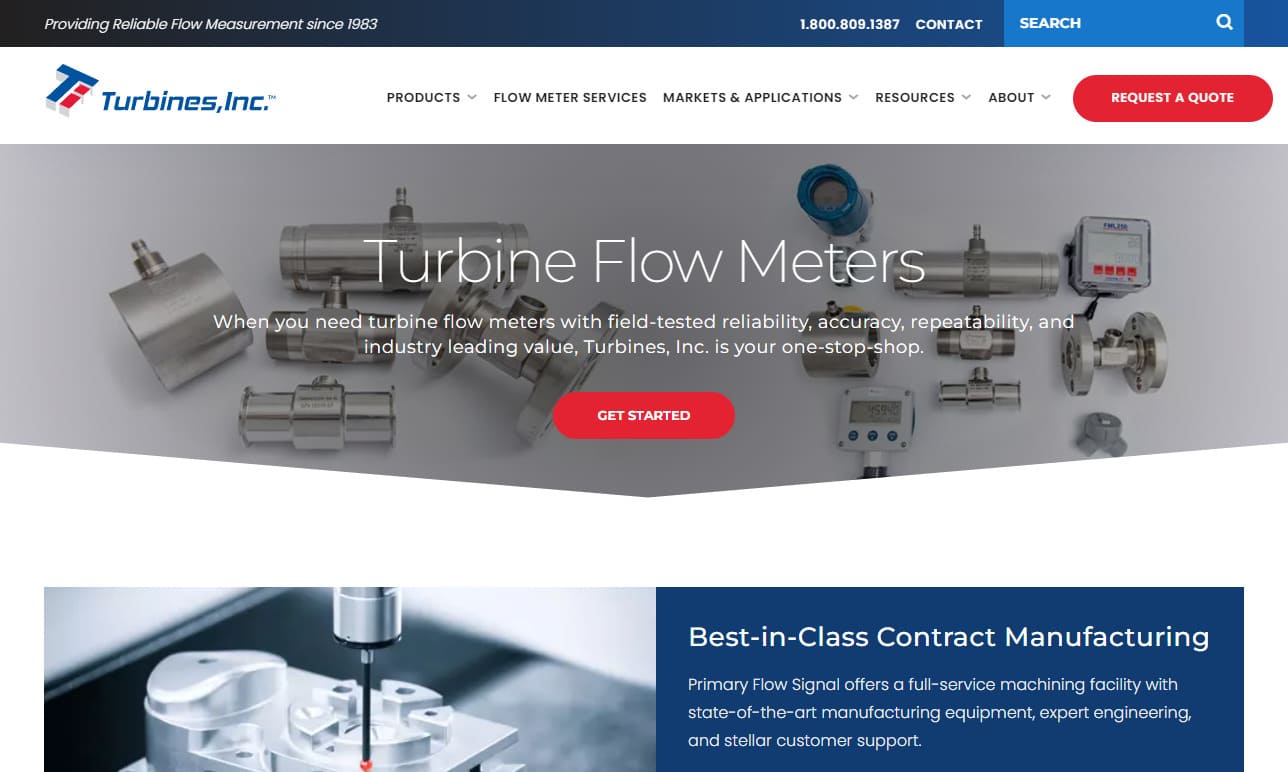

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

More Venturi Flow Meter Manufacturers

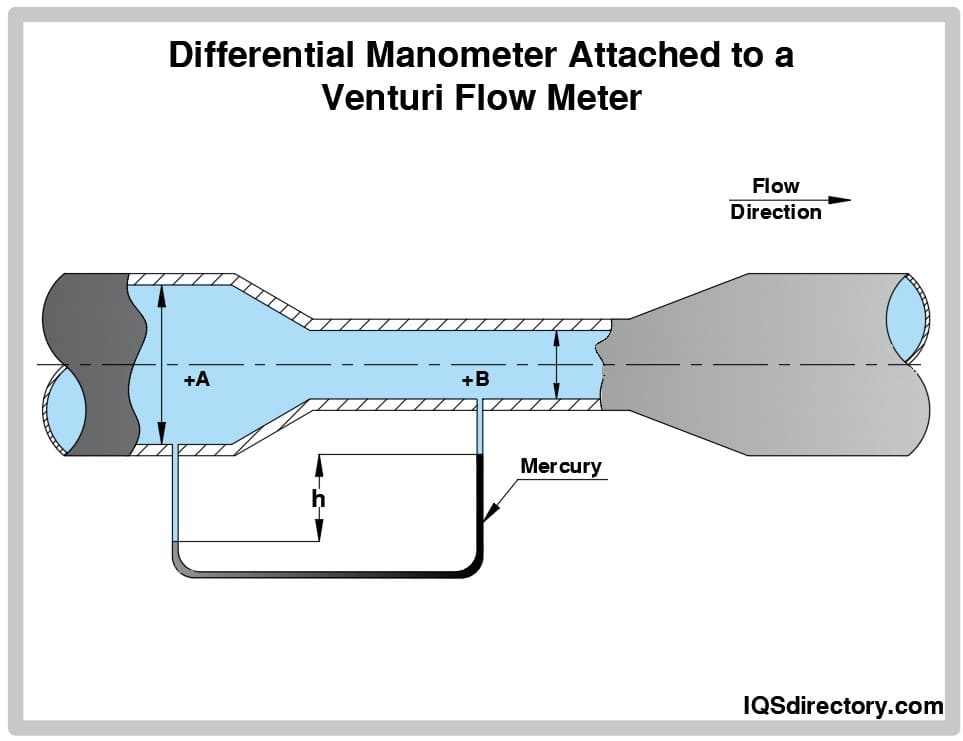

The pressure drop created by a Venturi flow meter is measured using a differential manometer pressure sensor. Calibration of the pressure drop is the flow rate of a fluid.

Bernoulli’s Principle

Bernoulli's Principle, or the Bernoulli effect, is one of the most important concepts regarding fluid dynamics and the relationship between fluid flow and fluid pressure. Fluid dynamics is the study of moving fluids, which is an essential aspect in regard to flow meters.

Swiss physicist Daniel Bernoulli developed the theory that if a fluid's speed increases, its static pressure and potential energy must decrease to compensate. This aspect of fluid theory relates to Venturi flow meters in that the constriction in the flow meter increases the velocity of a fluid. By doing so, the pressure in the fluid drops. The difference in the pressure outside and inside the constriction provides the necessary data to determine the flow rate.

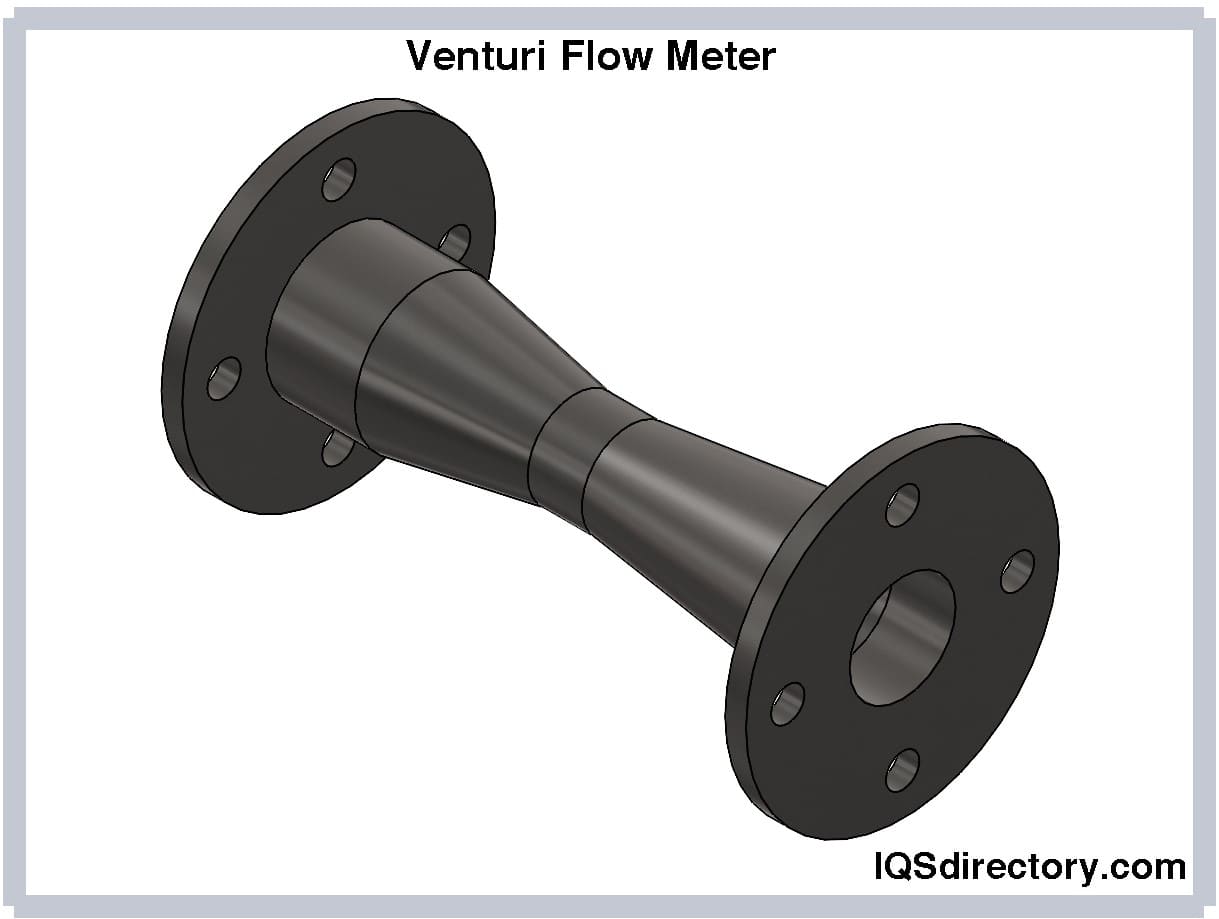

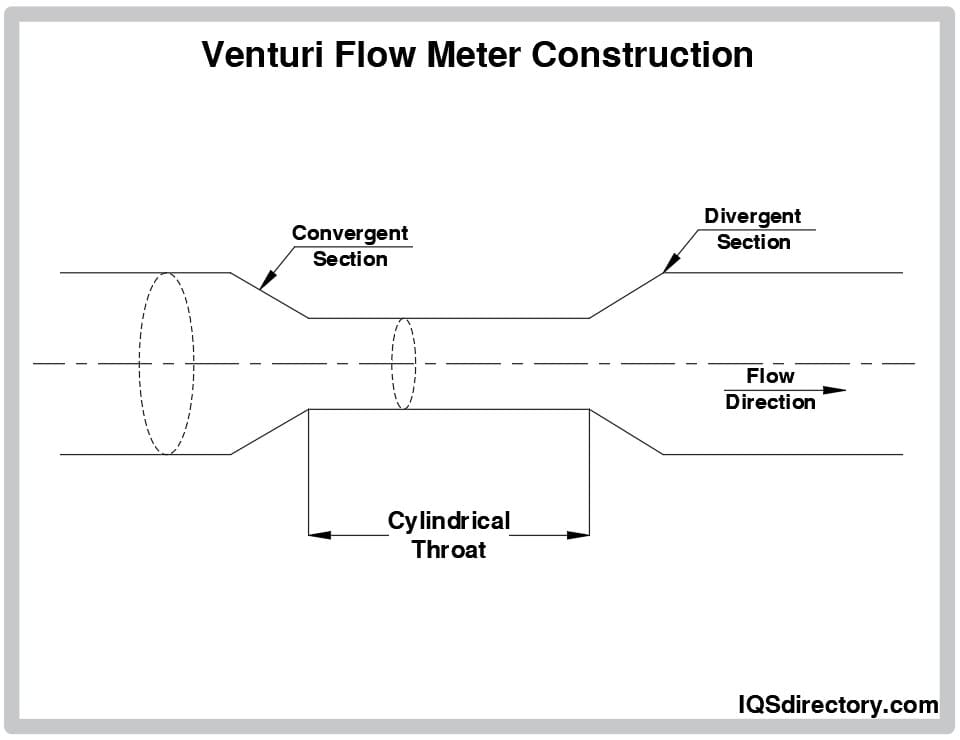

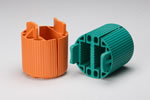

Venturi Flow Meter Construction

Venturi flow meters have a simple design, with each component of the flow meter arranged systematically. The parts of a Venturi flow meter include a converging cone, cylindrical throat, and diverging cone.

Converging Cone

The converging cone has a conical shape to connect to the throat and is attached to the inlet pipe or upstream flow. Its area decreases as its length approaches the connection to the throat. The angle of convergence is 20° to 22°, which is limited to avoid vena contracta. The decrease in the area of the converging cone causes the velocity of the fluid to increase and the pressure to decrease.

Cylindrical Throat

The cylindrical throat in the middle of a venturi flow meter is a major part of its working mechanism. The diameter of the throat is 0.25 to 0.75 of the inlet pipe's diameter and is constant throughout its length. The throat's diameter is designed to increase fluid velocity and decrease fluid pressure, which is below vapor pressure resulting in cavitation.

Diverging Cone

The diverging cone is the third and final part of a Venturi flow meter attached to the outlet pipe. From the beginning to the end of its length, its diameter increases at an angle of 5° to 15°. The diverging cone's small angle avoids flow separation and prevents eddies that can result in a loss of flow energy.

Differential Manometers

Differential manometers measure the pressure between a Venturi flow meter's convergent cone and cylindrical throat. They are ideal for Venturi flow meters since they are a method for pressure comparison and not a pressure-measuring instrument. The two types of differential manometers are U tubes and inverted U tubes.

U Tube

U tube differential manometers have a glass tube bent into a U shape, with the ends of the U shape connected to two points on a Venturi flow meter. The U glass tubing is filled with a manometric fluid, mainly Mercury, with a specific gravity higher than the liquid in the pipe. In the case of Venturi flow meters, one limb of the manometer is connected to the convergent cone with the other limb connected to the throat. The level of manometric fluid will be lower in the convergent cone than in the throat.

Inverted U Tube

An inverted U tube manometer follows the same principle as a U tube manometer except that it is attached above the Venturi flow meter and the horizontal pipe. It uses a lighter manometer liquid to prevent the liquid from entering the flow stream. As with a U tube manometer, the limbs of the tube are connected to the convergent cone and throat of the Venturi flow meter.

Benefits of a Venturi Flow Meter

Venturi flow meters are a versatile and adaptive solution for flow measurement that can fit any defined space and are a reliable method for billing or custody transfer. They can be oriented on any plane and accurately measure regardless of a fluid's directional flow.

Advantages of Venturi Flow Meters:

- Simplicity of Design

- Durability

- Long Life of Usefulness

- Exceptional Accuracy

- Compact Shape

- Cannot Clog

- Very Little Maintenance

- Easy Installation

Choosing the Correct Venturi Flow Meter Manufacturer

To ensure the most beneficial outcome when purchasing Venturi flow meters from a Venturi flow meter manufacturer, it is important to compare several companies using our directory of Venturi flow meter manufacturers. Each manufacturer has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Venturi flow meter business website using our proprietary website previewer to quickly learn what each company specializes in. Then use our simple RFQ form to contact multiple Venturi flow meter businesses with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services