This type of flow meter is dubbed the Coriolis because it utilizes the Coriolis effect, an inertial force that is caused by the Earth’s rotation, in order to obtain a highly accurate measurement of mass flow as well as the density of the fluid. A relatively new type of flowmeter, Coriolis flow meters began being used in industrial applications in the early 1980’s. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

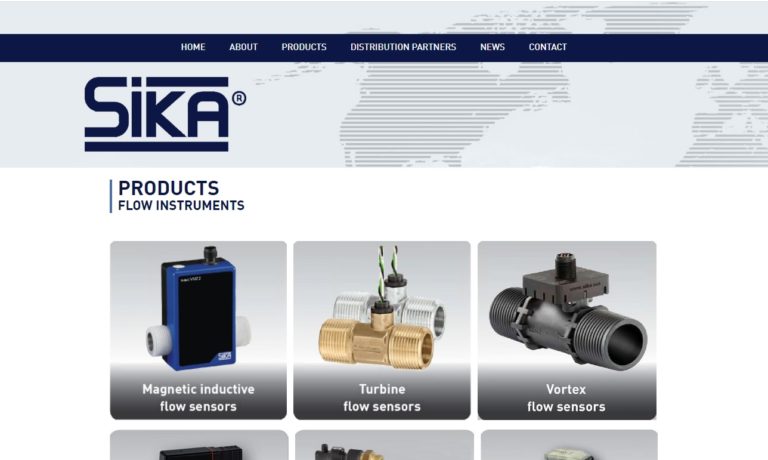

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

More Coriolis Flow Meter Manufacturers

Additional applications of Coriolis flow meters include continuous blending, combustion control, fermentation, fueling, vial filling, bottling, and concentration measurements. As a result, Coriolis flow meters are not only useful in the industrial manufacturing industry, but in a wide range of industries including petrochemical, food and chemical processing, automotive, and pharmaceutical.

Coriolis flow meters are typically constructed from a U-shaped flow tube (which is filled with fluid but has not flow), a driving unit and displacement sensors, with an inlet and an outlet to allow for flow.

To begin, the flow is guided into the flow tube from the inlet, from which point an oscillating excitation force is applied to the tube in order to cause vibration. Once the vibration is achieved, the flow of the fluid will cause a rotation of the tube caused by the Coriolis effect. This effect causes rotation because it causes acceleration on one side of the tube (the inlet) and deceleration on the other side of the tube (the outlet). As a result, the inlet is able to register the flow before the outlet is able to, which results in a time delay. This time delay is directly proportional to the mass flow rate of the fluid or gas.

Coriolis flow meters are able to measure the mass flow rates of a broad spectrum of fluids and gasses including hydrogen gas, bitumen, natural gas, and water. Since some of the fluids or gasses are corrosive, Coriolis flow meters are often constructed from such corrosion-resistant materials as stainless steel and hastelloy.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services